DTH Down the Hole Hammers and Bits

DTH Hammer Information

Selecting the right DTH Hammer

The optimum range of hole size for blast hole drilling with DTH is 90 mm to 254 mm (3 ½”–10″). Smaller blast holes are generally drilled using tophammer, and larger holes generally use rotary machines.

In other applications, like foundation drilling, DTH hammers can be used with single bit in hole sizes up to . 750 mm (30″). With multiple hammer units CD (Cluster drills) drill holes up to 70″ or 1778 mm.

As a rule of thumb, the smallest hole diameter a DTH hammer can drill is its nominal size. A 4 inch hammer will drill a 4 inch (102 mm) hole. The limiting factor is the outside diameter of the hammer, because, as hole diameter reduces, airflow is restricted. Maximum hole size for production drilling is the nominal hammer size plus 1 inch, so for a 4 inch hammer the maximum hole size is 5 inch (127–130 mm).

Choosing the right hammer is largely determined by hole size and type of rock formation. Ideally, the size of the hammer should match the required hole dimension as closely as possible, leaving just enough space for cuttings to evacuate the hole.

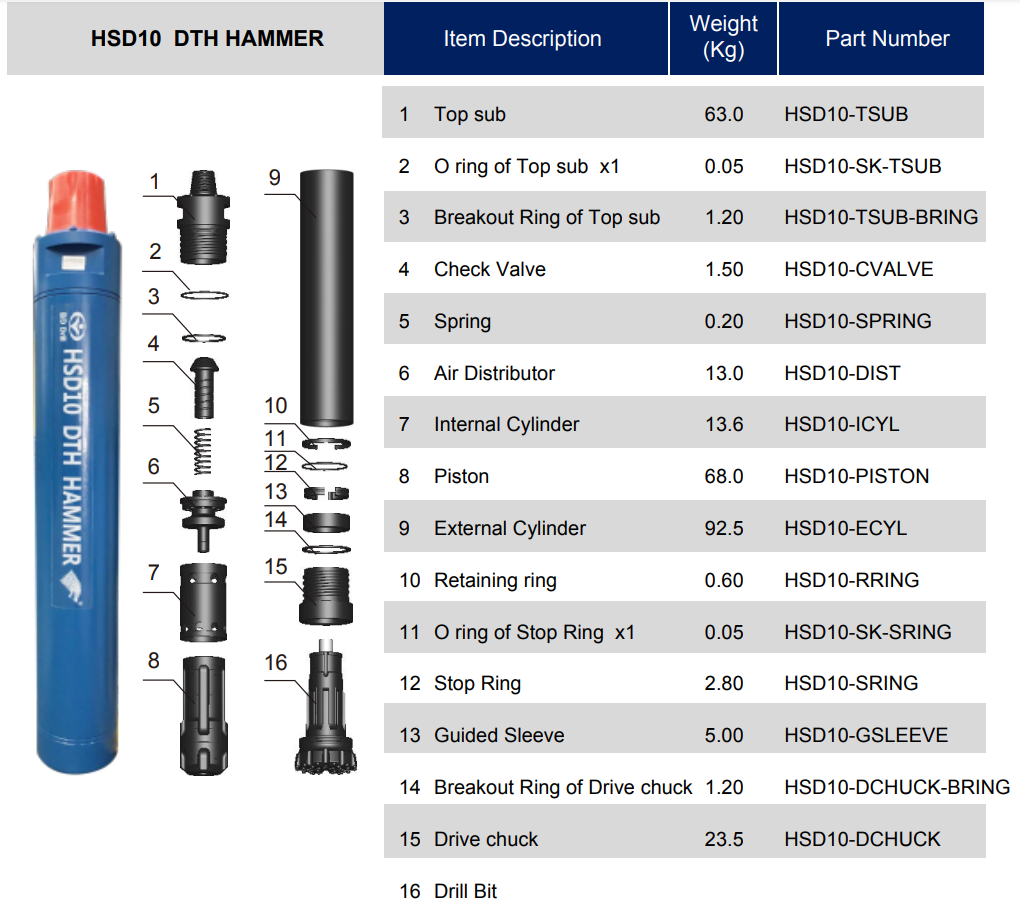

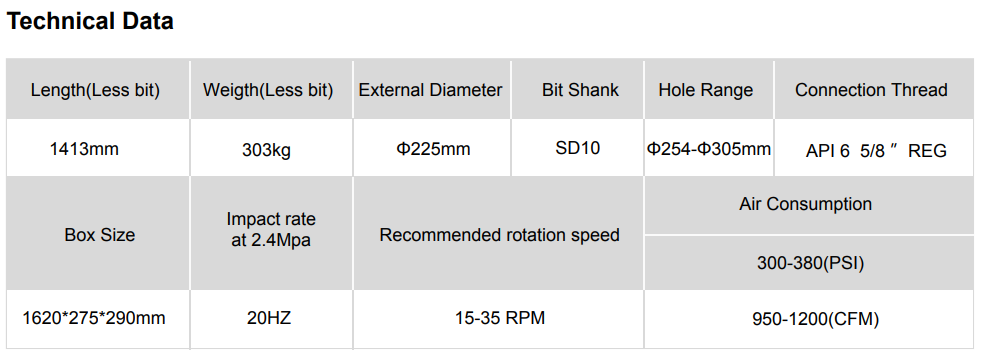

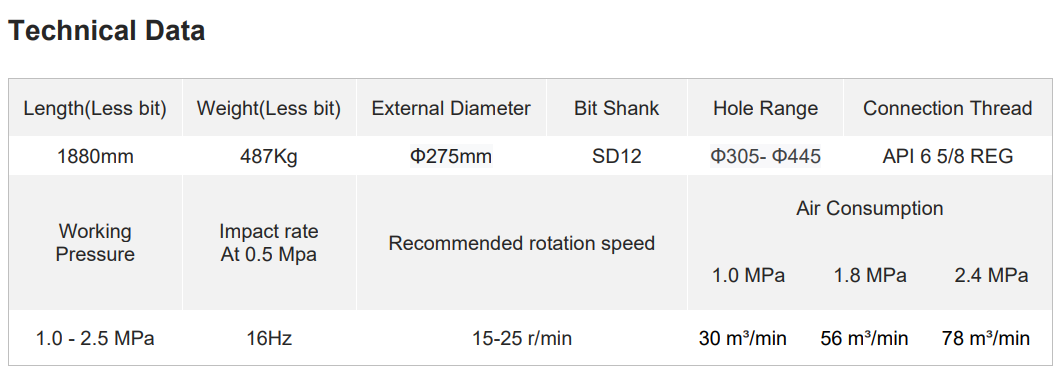

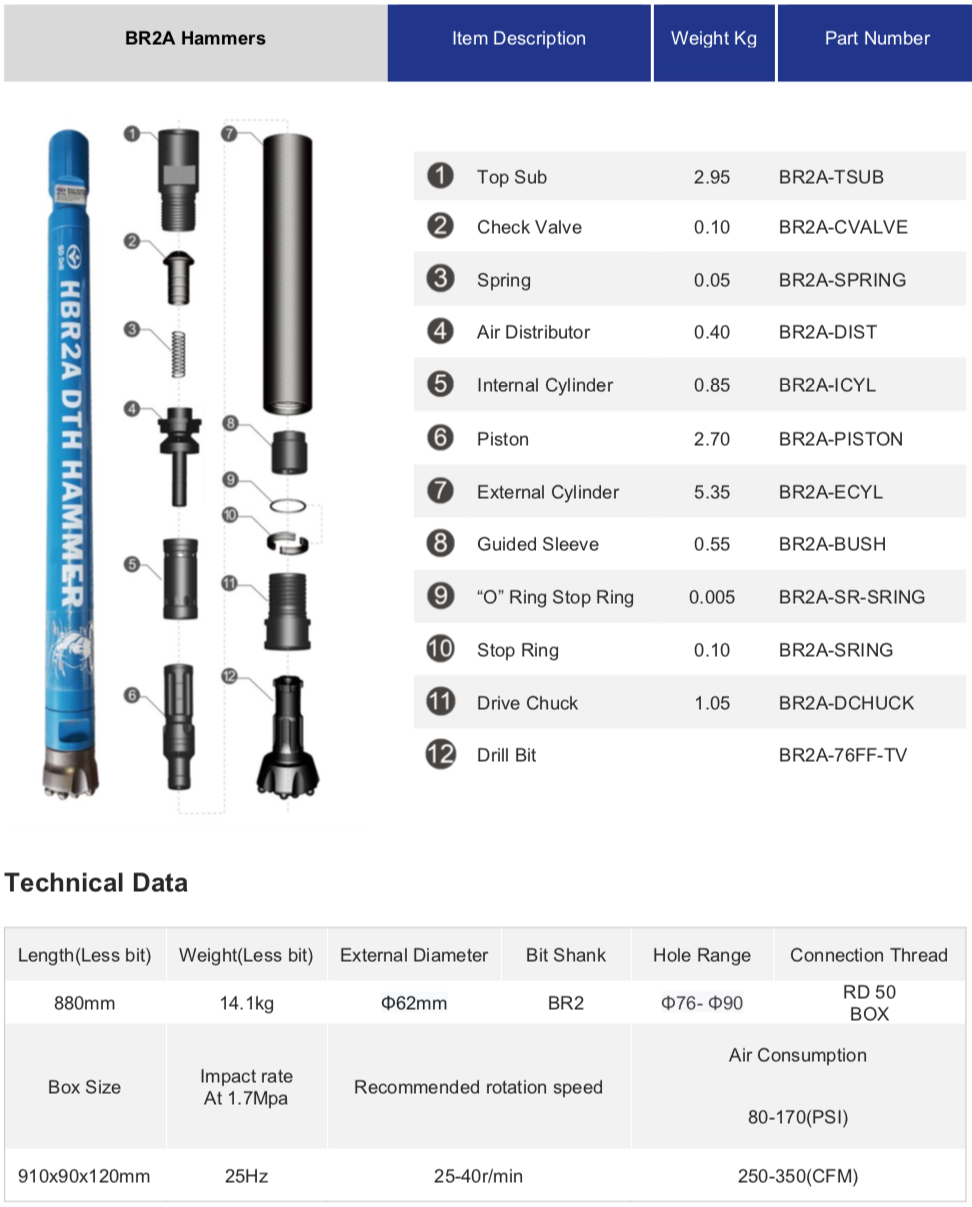

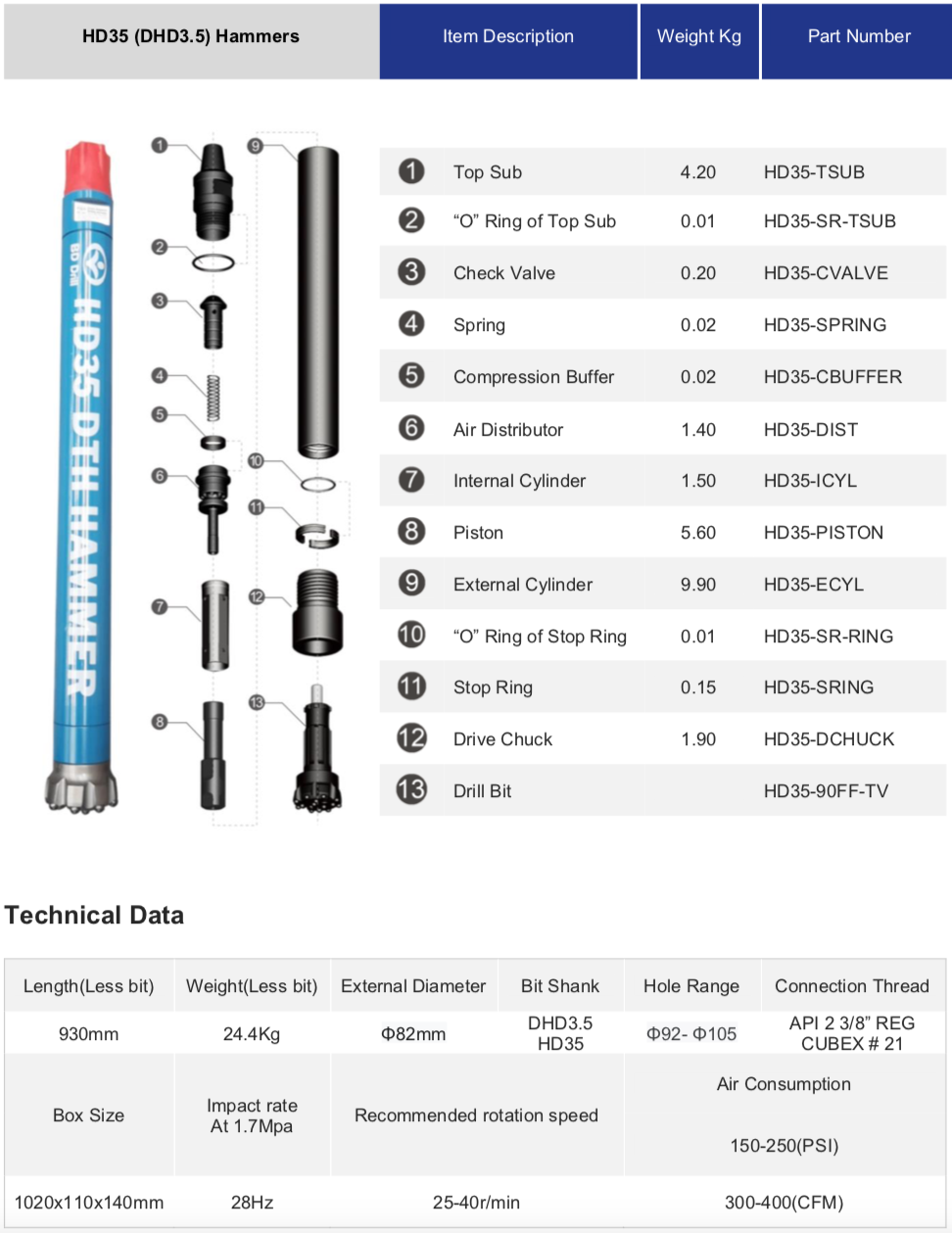

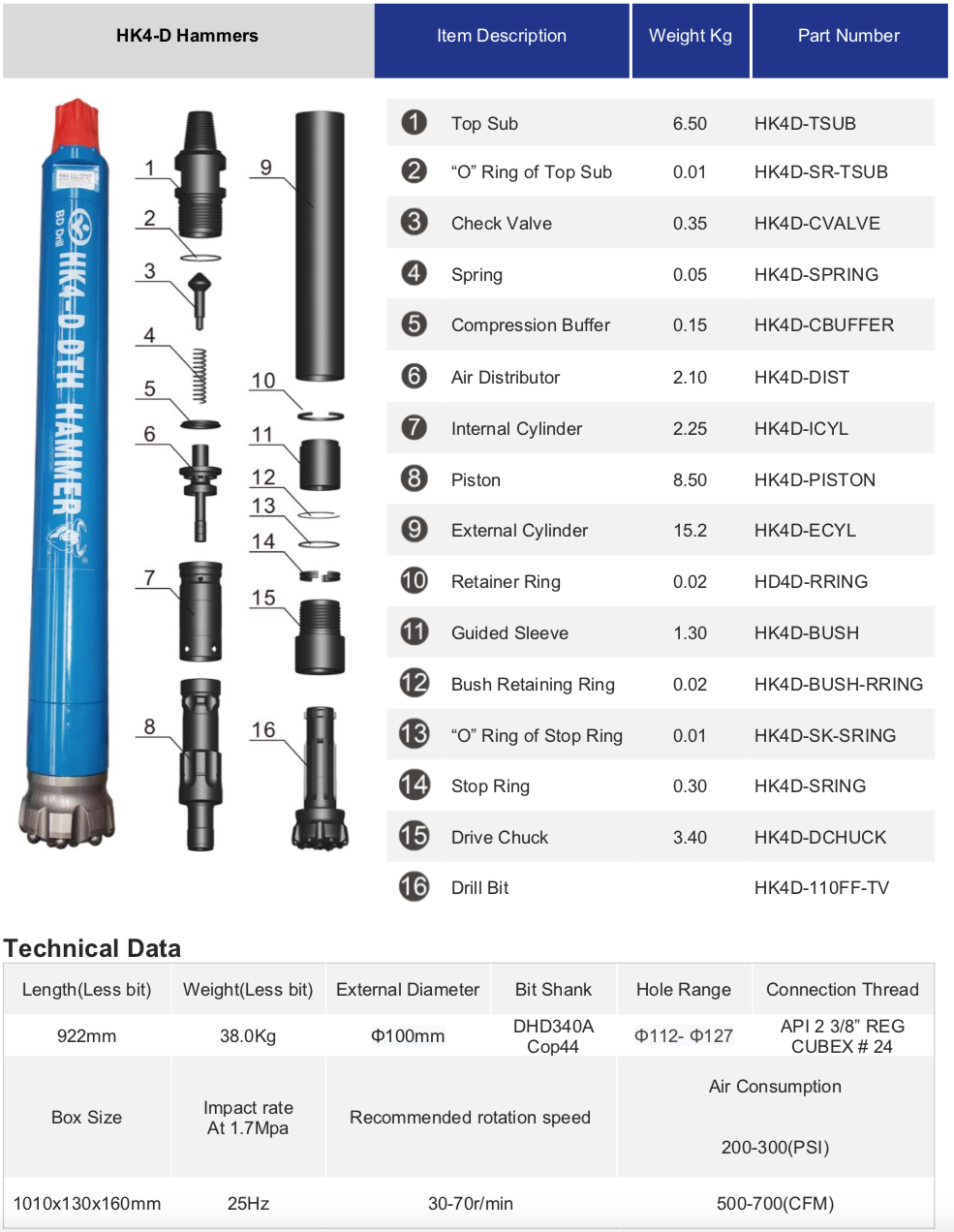

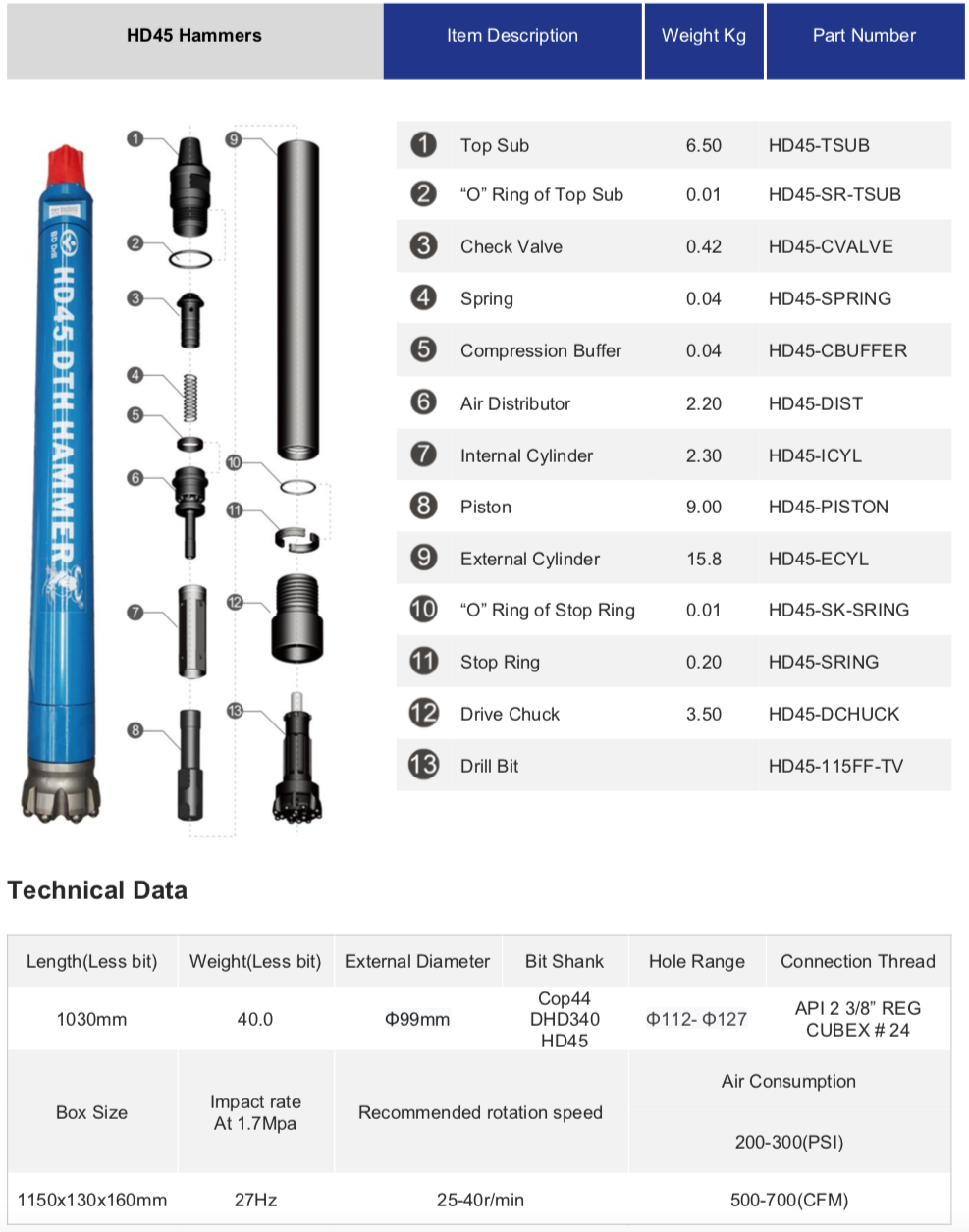

| Hammer | BR2A | DHD3.5 | HK4D | HD45 | HQL4A | HQL50 | HK5Q | HD55 | HQL60 | HQL6A | HQL80 | HD85 | HK9Q | HSD10 | HSD12 | HK12Y | N125-R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Recommended bit size, mm | 76 | 92-105 | 112-127 | 140-152 | 165-178 | 203-229 | 216-229 | 245-305 | 305-445 | 305-350 | 305-445 | ||||||

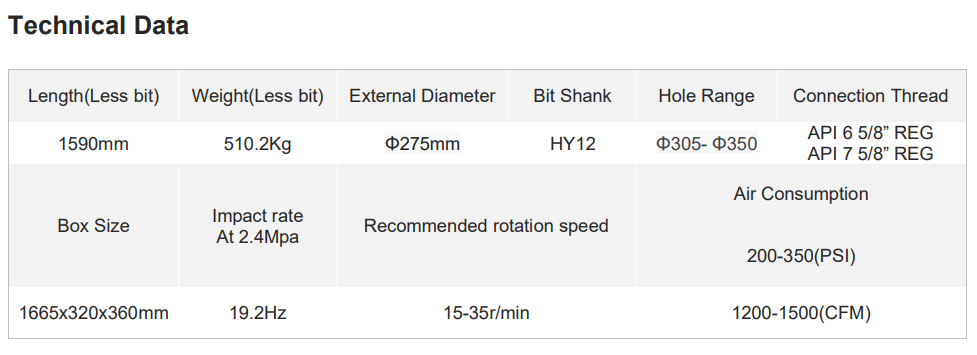

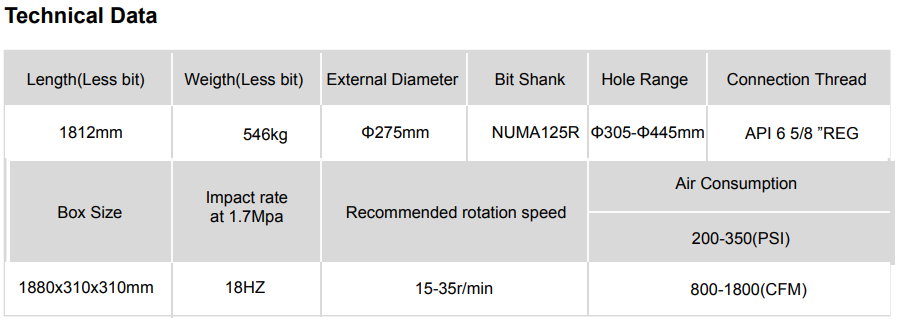

| Bit Shank | BR2A | DHD3.5 | DHD340A | QL40 | QL50 | DHD350 | QL60 | QL80 | DHD380 | QL80 | SD10 | SD12 | HY12 | NUMA125R | |||

| External diameter, mm | 63 | 82 | 100 | 100 | 101 | 126.5 | 127.5 | 126.5 | 148 | 146 | 185 | 185 | 203 | 225 | 275 | 275 | 275 |

| Length excl. thread, mm (Less bit) | 837 | 855 | 915 | 1032.5 | 1057 | 1147 | 935 | 1167 | 1121 | 1182 | 1471 | 1487 | 1345 | 1413 | 1680 | 1590 | 1812 |

| Hammer weight, kg (Less bit) | 14.1 | 25 | 37.5 | 40.6 | 41 | 71.6 | 67.6 | 77.2 | 105 | 105 | 203 | 206 | 228 | 303 | 526 | 510.2 | 546 |

| Package case size | (L)910 (W)90 (H)120 | (L)1200 (W)110 (H)140 | (L)1010 (W)130 (H)160 | (L)1080 (W)125 (H)134 | (L)1150 (W)130 (H)160 | (L)1290 (W)150 (H)175 | (L)1100 (W)155 (H)180 | (L)1290 (W)150 (H)175 | (L)1270 (W)170 (H)200 | (L)1260 (W)180 (H)200 | (L)1440 (W)230 (H)270 | (L)1560 (W)230 (H)270 | (L)1500 (W)240 (H)280 | (L)1620 (W)275 (H)290 | (L)1880 (W)320 (H)320 | (L)1665 (W)320 (H)360 | (L)1880 (W)310 (H)310 |

| Top Sub thread | RD50 | 2-3/8″ API REG | 3-1/2″ API REG | 4-1/2″ API REG | 6-5/8″ API REG | 6-5/8″ API REG 7-5/8″ API REG | 6-5/8″ API REG |

||||||||||

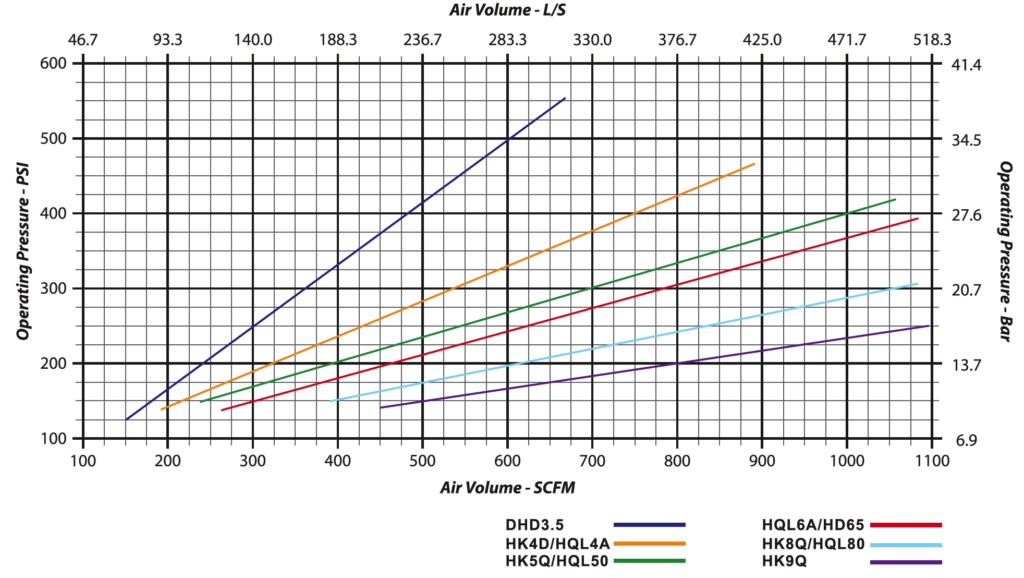

| Working Pressure, PSI | 80-170 | 150-250 | 200-300 | 250-350 | 300-350 | 300-380 | 300-380 | 150-350 | 200-350 | ||||||||

| Air consumption, CFM | 250-350 | 300-400 | 500-700 | 500-800 | 600-900 | 950-1200 | 950-1200 | 1000-1800 | 1200-1500 | 800-1800 | |||||||

| Piston diameter, mm | 42.7 | 65 | 82 | 80 | 80 | 104 | 102 | 100 | 122 | 121 | 150 | 150 | 165 | 185 | 225 | ||

| Piston weight, kg | 1.7 | 5.1 | 9.2 | 9 | 9 | 17 | 17 | 16 | 24 | 24 | 38 | 42 | 50 | 68 | 110 | 111 | 111 |

| Wrench flat, mm | L47 W50 | L57 W35 | L74.5 W45 | L64 W40 | NO wrench flat | L89 W60 | L88 W50 | L89 W60 | L101 W65 | L101 W60 | L128 W70 | L140 W70 | L128 W70 | L140 W70 | L140 W70 | L140 W70 | L140 L70 |

| Feed force, kN | 2~6 | 3~8 | 5~15 | 6~25 | 7~20 | 10~25 | 15~30 | 20~35 | |||||||||

| Rotation speed, r/min | 30-70 | 3-90 | 25-80 | 20-70 | 25-60 | 20-60 | 15-35 | ||||||||||

| Drilling conditions and project specifications may require larger air package to be used | |||||||||||||||||

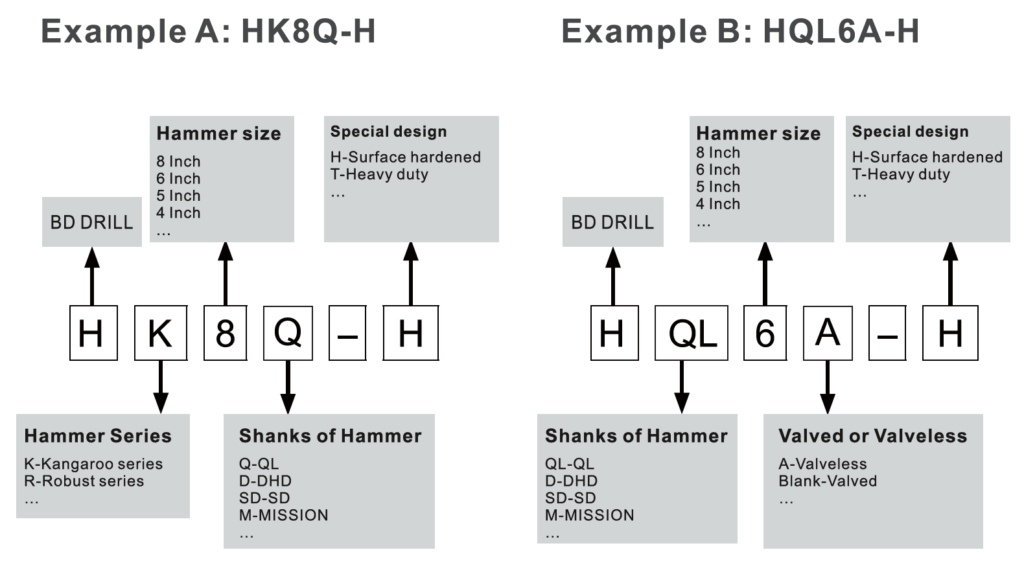

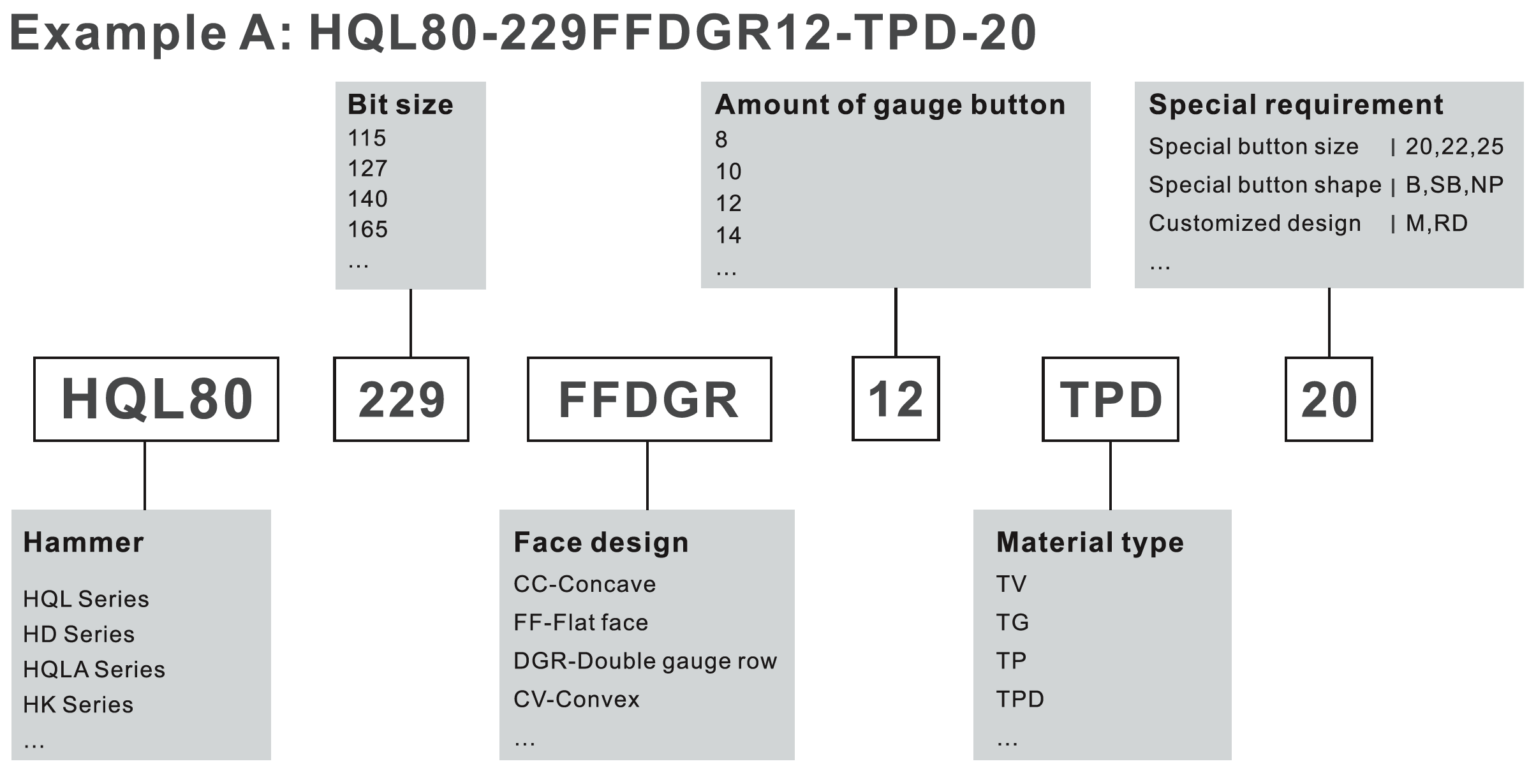

Product codes are a valuable tool to describe and identify the product. In the code structure we have tried to describe the product features with an alphanumeric system and not always 100% logical, but with the attached key you will be able to find the product you are looking for or alternative products.

DTH Down the Hole Hammers Product List

Download PDF | Compatibility: BR2, COP20

Download PDF | Compatibility: DHD3.5, COP35, TD35, QLX35, TERRANOX

Download PDF | Compatibility: DHD340A, COP44, QL340, TERRANOX 4

Download PDF | Compatibility: DHD340A, COP44, QL340, TERRANOX 4

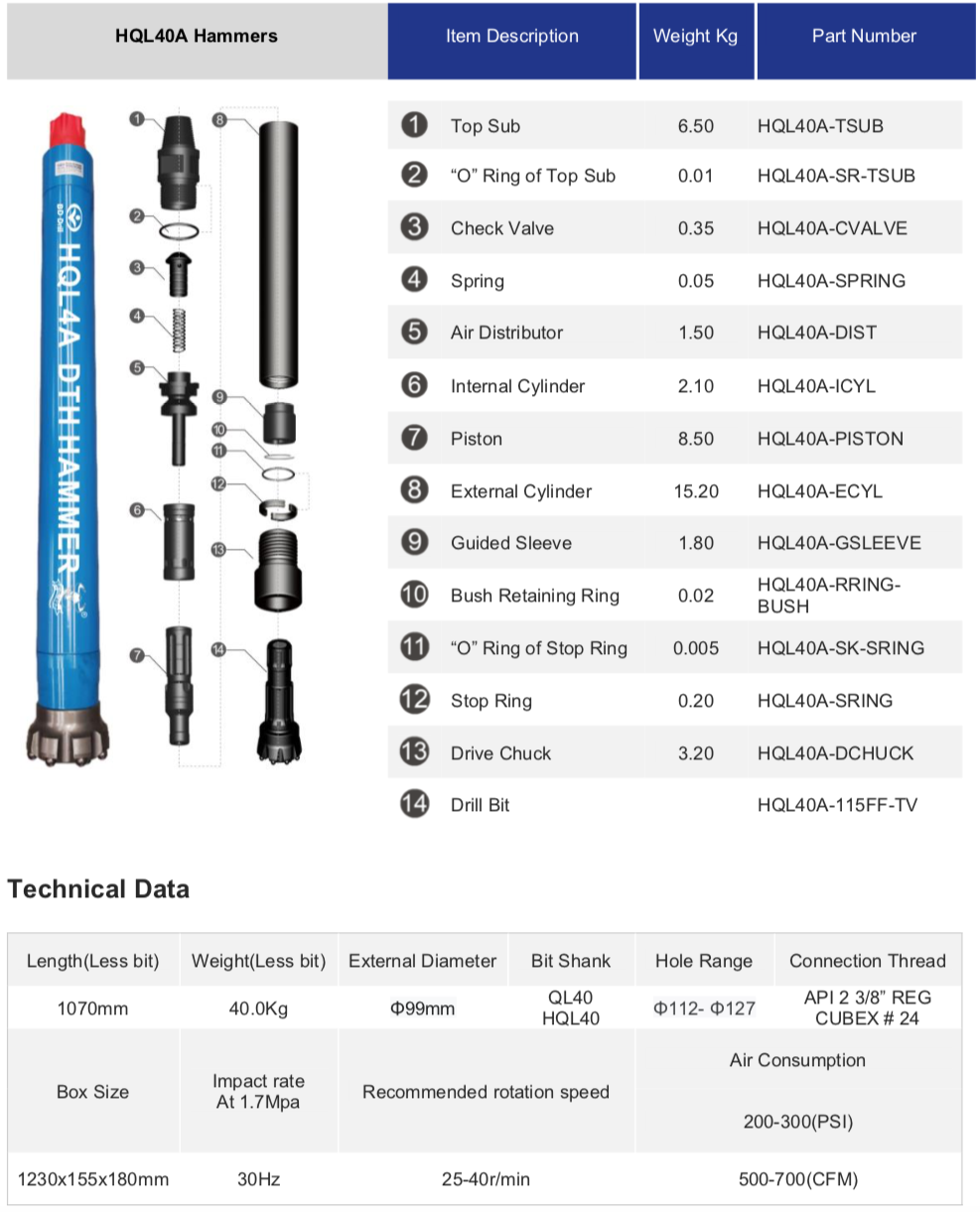

Download PDF | Compatibility: QL40

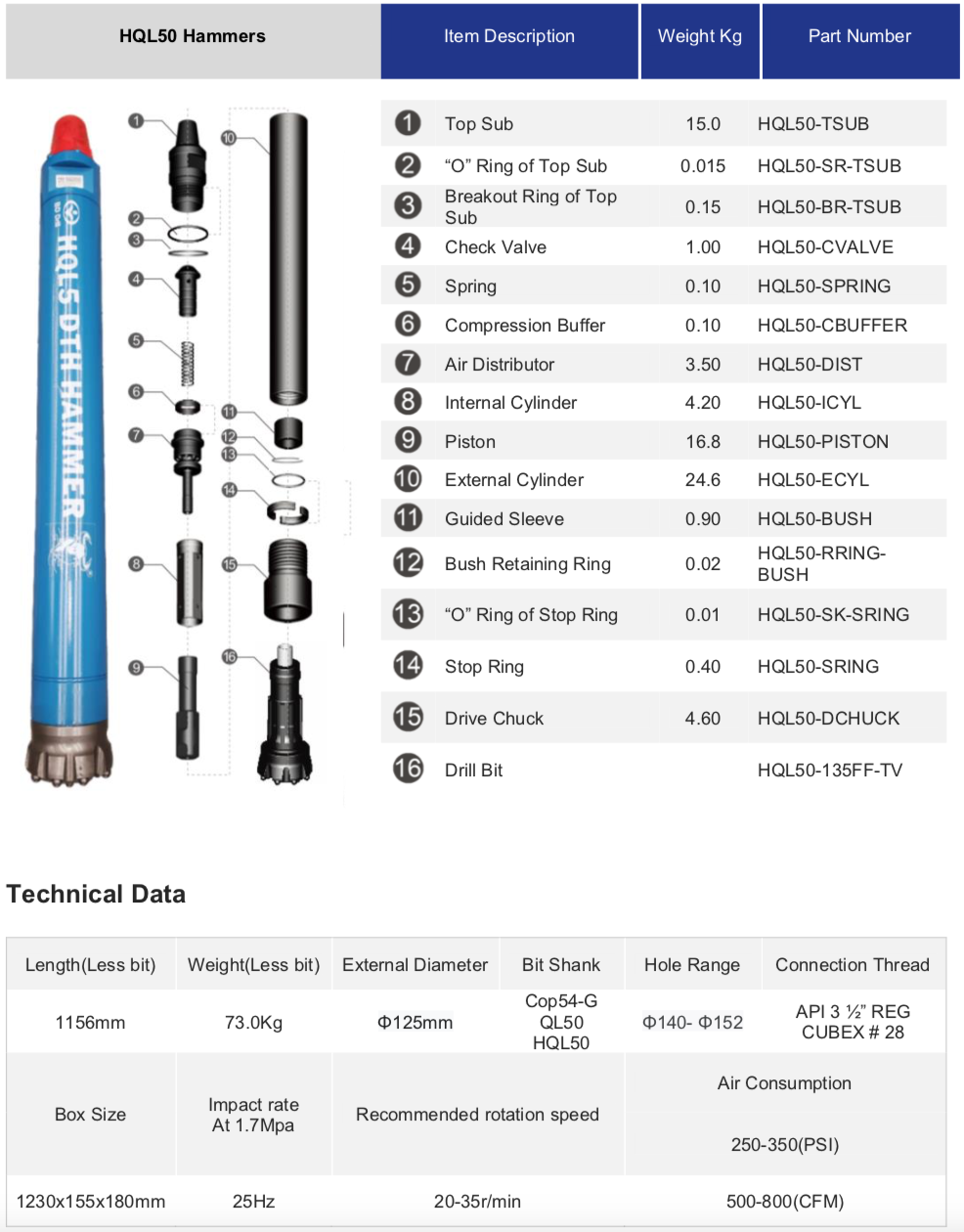

Download PDF | Compatibility: QL50, TD50, COP54G

Download PDF | Compatibility: QL50, TD50, COP54G

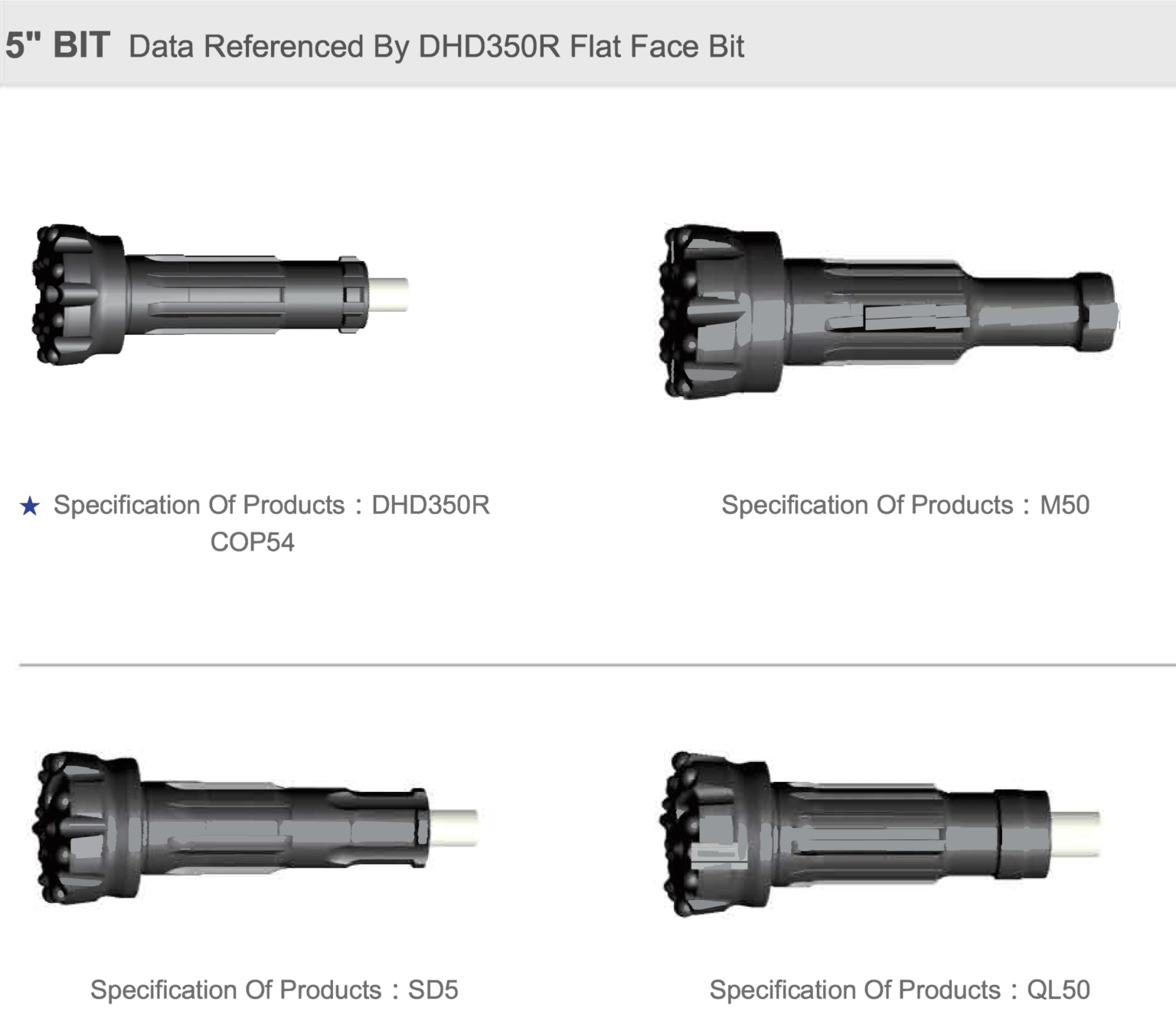

Download PDF | Compatibility: COP54, TERRANOX 5

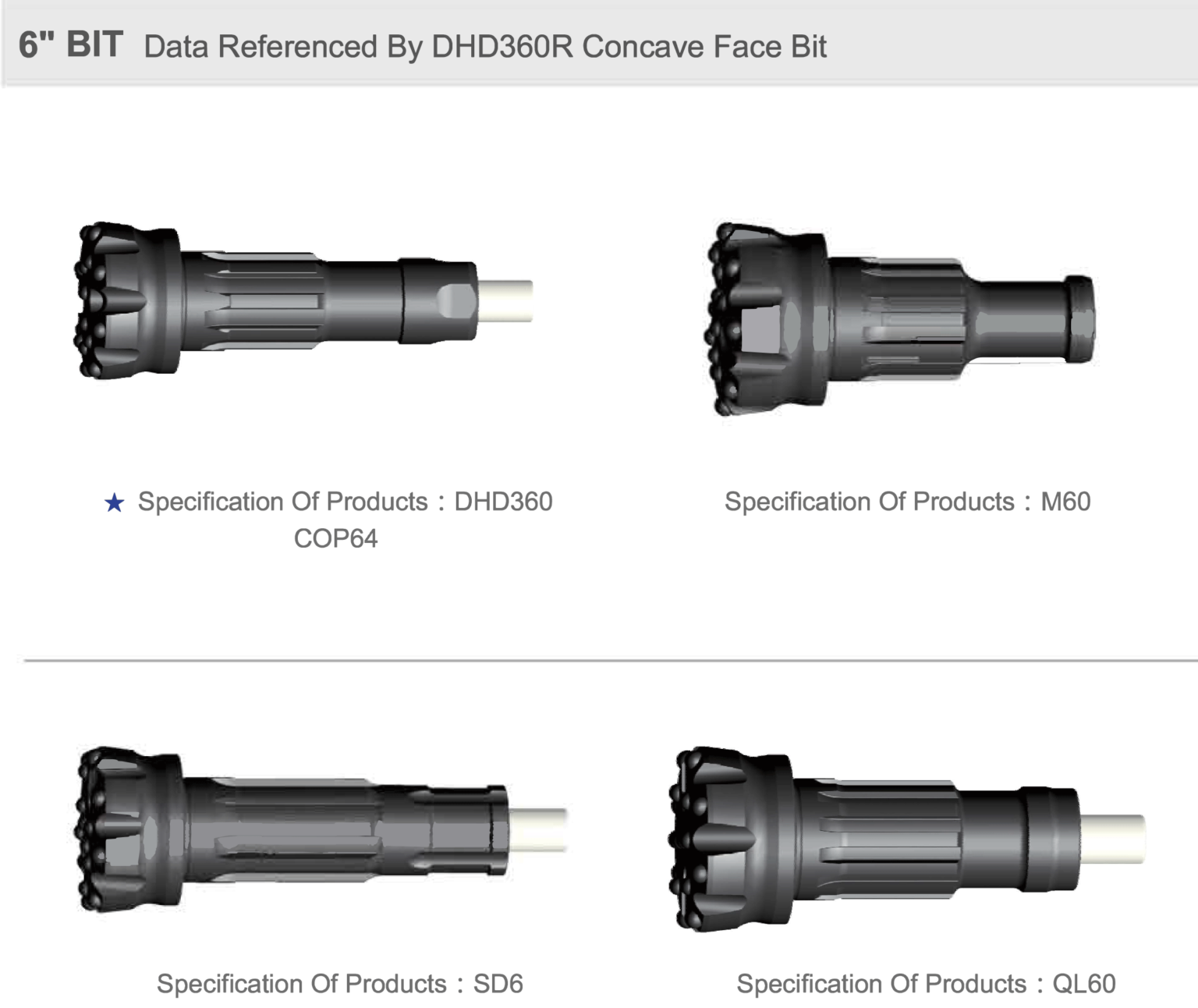

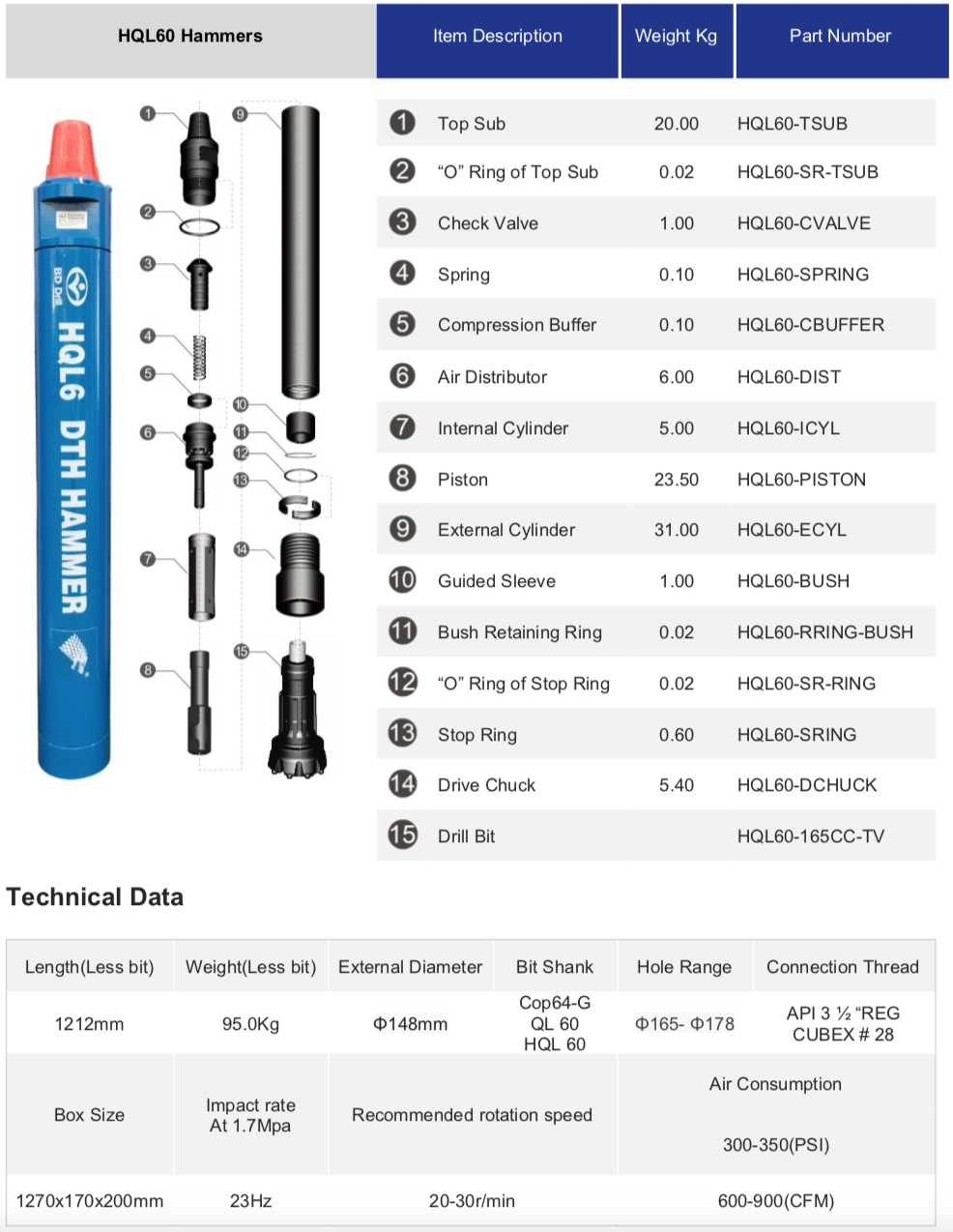

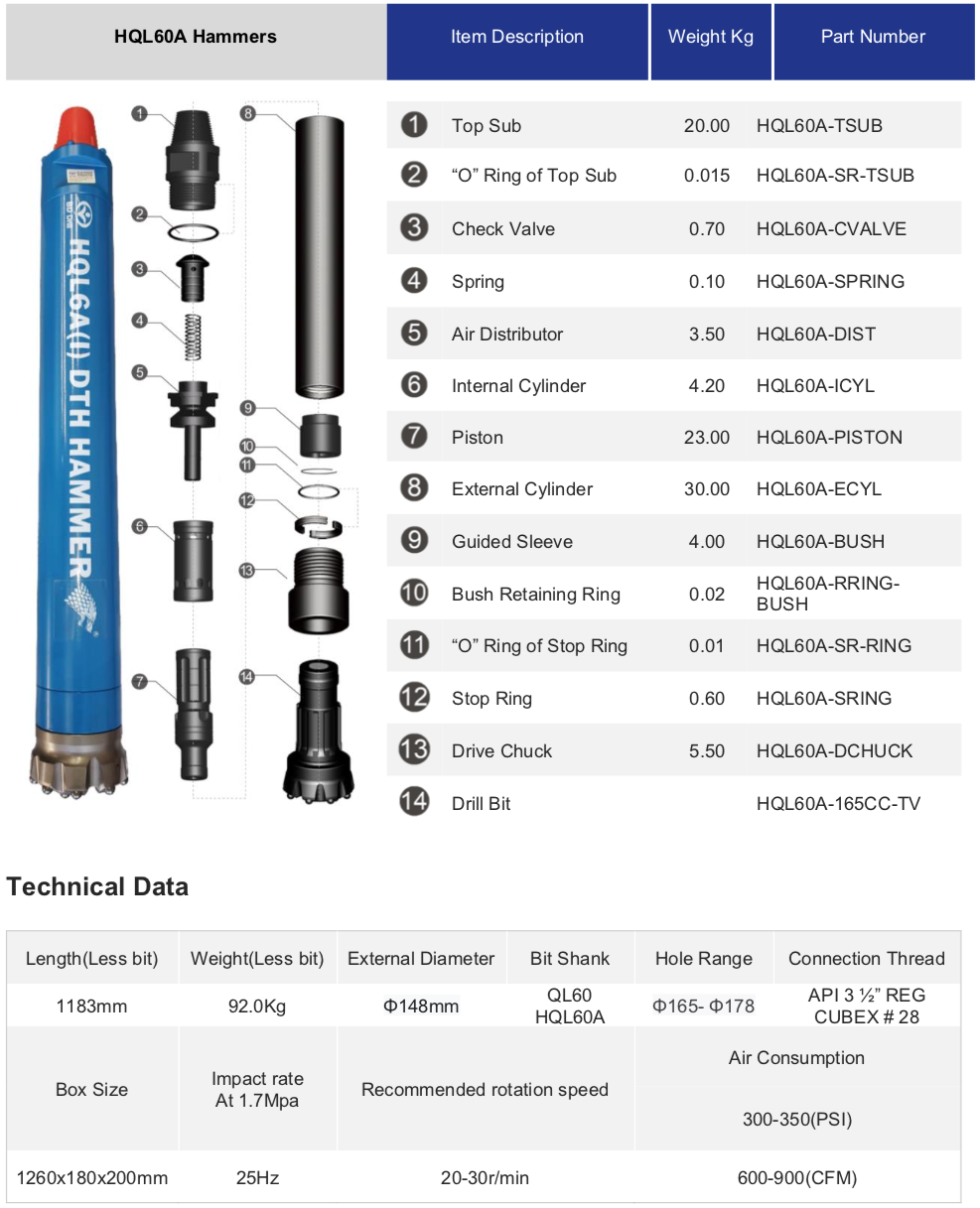

Download PDF | Compatibility: QL60, COP64G

Download PDF | Compatibility: QL60, COP64G

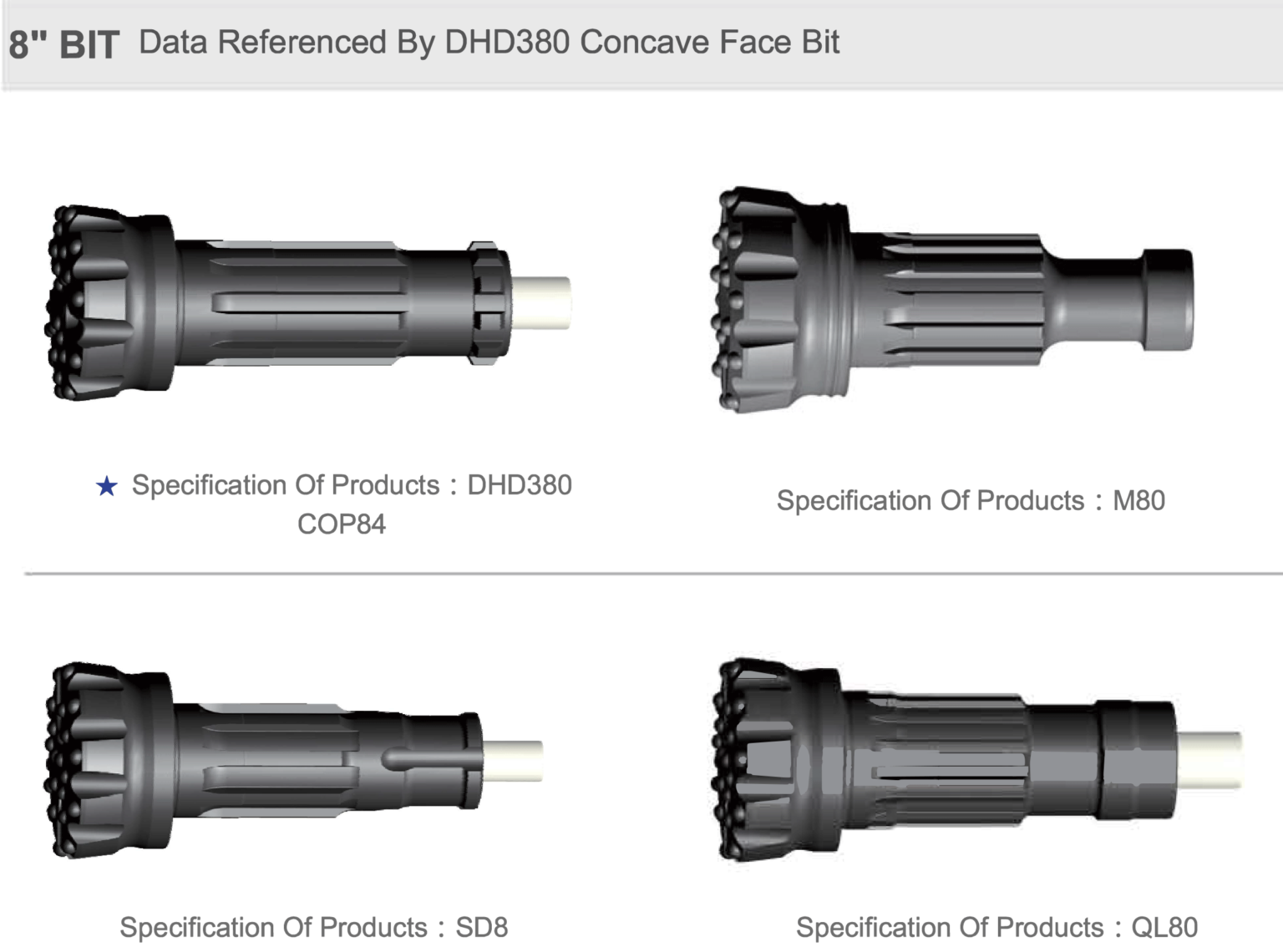

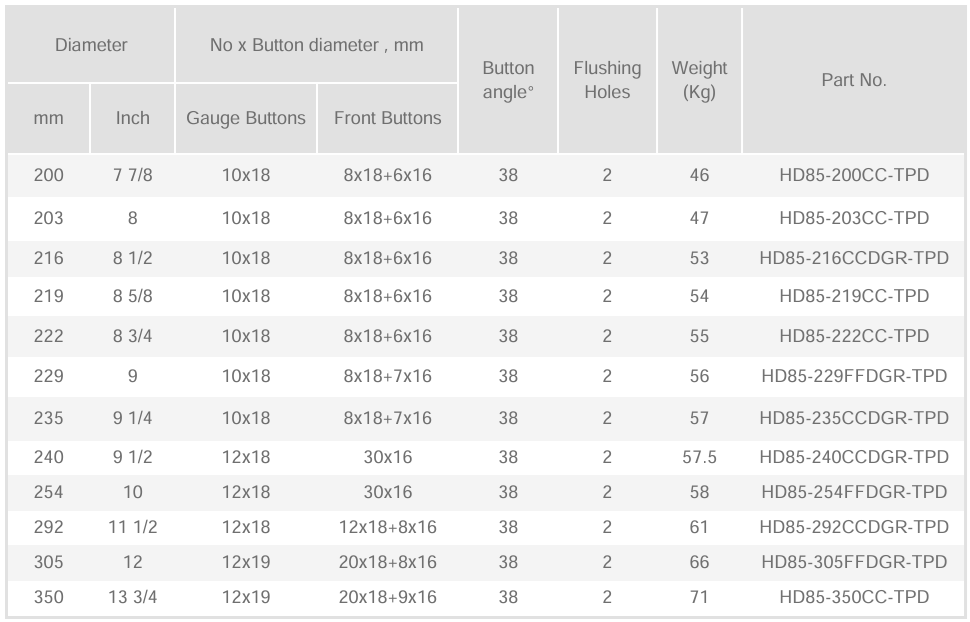

Download PDF | Compatibility: QL80, TD80, TD85

Download PDF | Compatibility: DHD380, TERRANOX 8

DTH Down the Hole Bits Information

Selecting the right bit

Black Diamond has a comprehensive range of DTH drill bits to match all conceivable applications. Each bit is made from quality alloy steel, and has been precision machined to produce a perfect body, heat treated to the required hardness, given surface compression for fatigue resistance, and fitted with precision buttons manufactured in-house. These are deigned for specific applications for all rock types, hardness’s and condition. Bit life and rate of penetration are the most important criteria in selecting the right bit for a particular application.

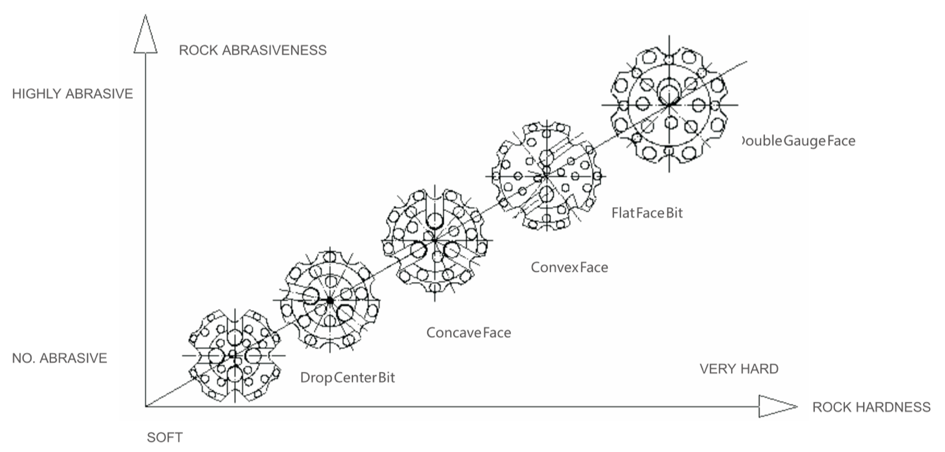

For high penetration rates in soft to medium hard and fissured rock formations. Low to medium air pressures. Maximum hole deviation control.

For high penetration rates in soft to medium-hard with low to medium air pressures. It is the most resistance to steel wash and may reduce the load and wear on the gauge buttons. However, it has poor hole deviation control.

For high penetration rates in soft to medium-hard with low to medium air pressures. It is the most resistance to steel wash and may reduce the load and wear on the gauge buttons. However, it has poor hole deviation control.

This kind of face shape is suitable for fast penetration rates in medium to hard rock formations. Designed for high air pressures and good resistance to steel wash step gauge bit.

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressures. Good penetration rates and resistance to steel wash.

The Pineapple Bit can be dressed with ballistic buttons for use in soft to medium hard formations where fractured rock can be expected, or can be supplied with spherical buttons for hard and abrasive formations.

DTH Down the Hole Bit Shape technical Data

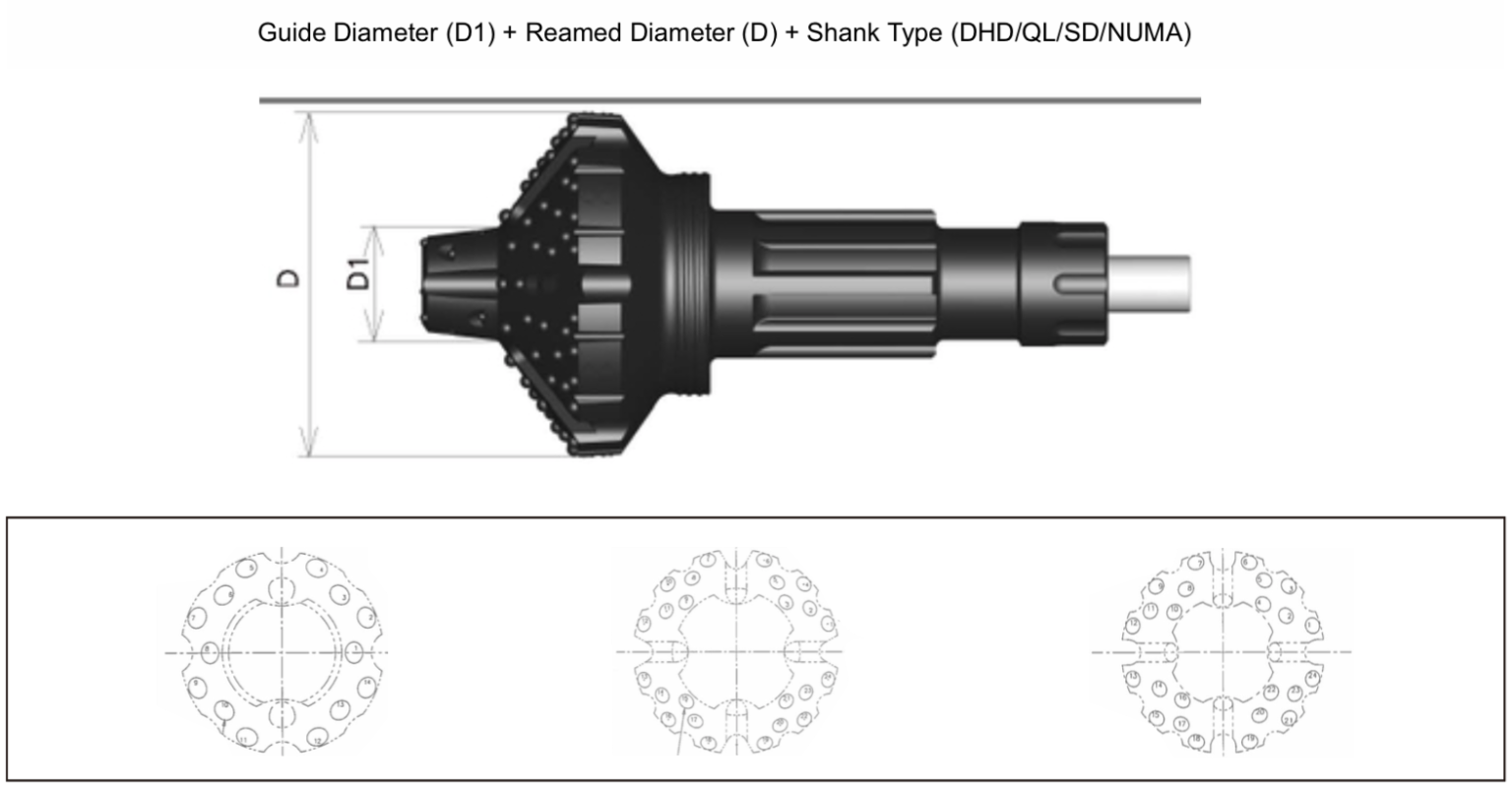

DTH Down the Hole Bits Product Codes

Product codes are a valuable tool to describe and identify the product. In the code structure we have tried to describe the product features with an alphanumeric system and not always 100% logical, but with the attached key you will be able to find the product you are looking for or alternative products.

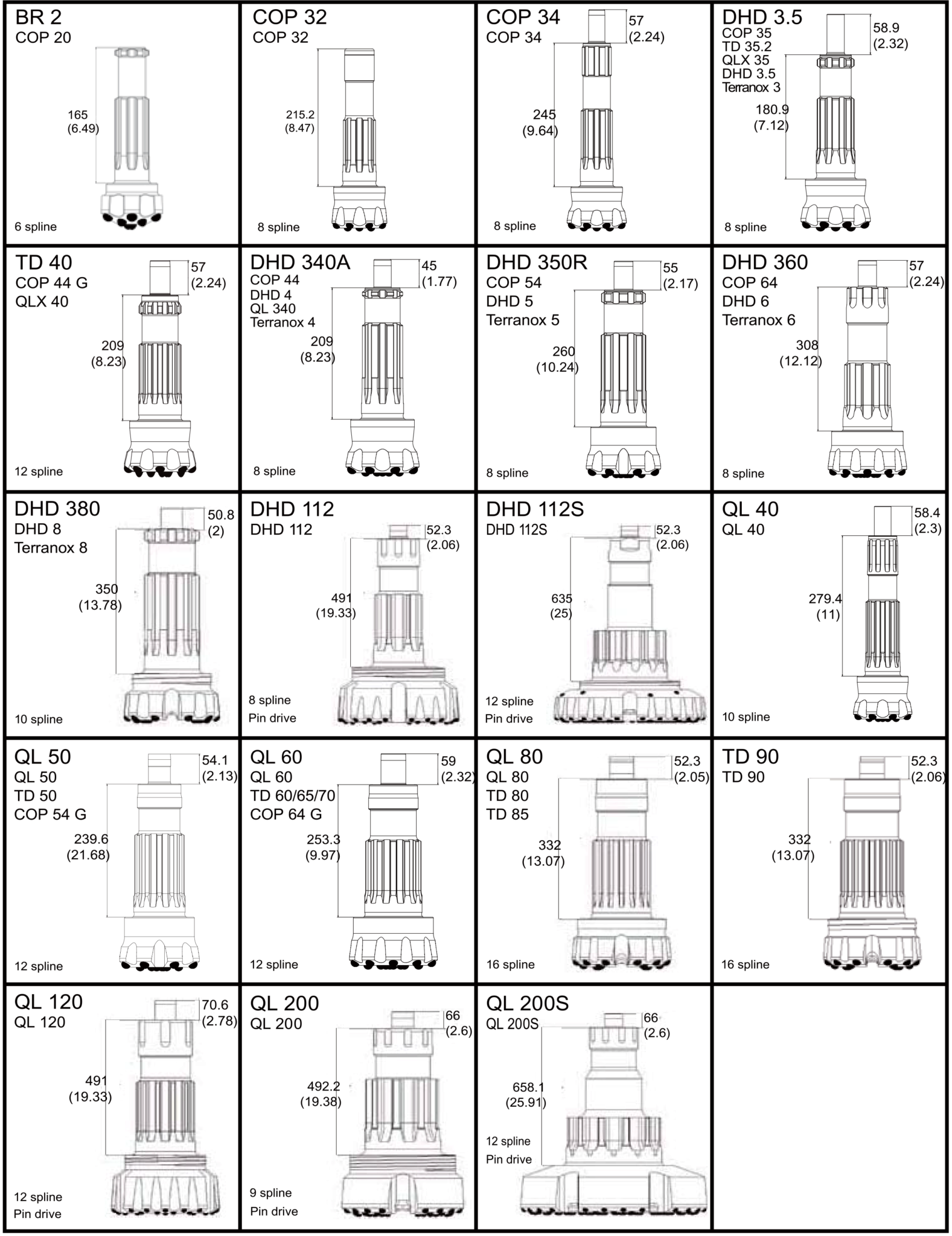

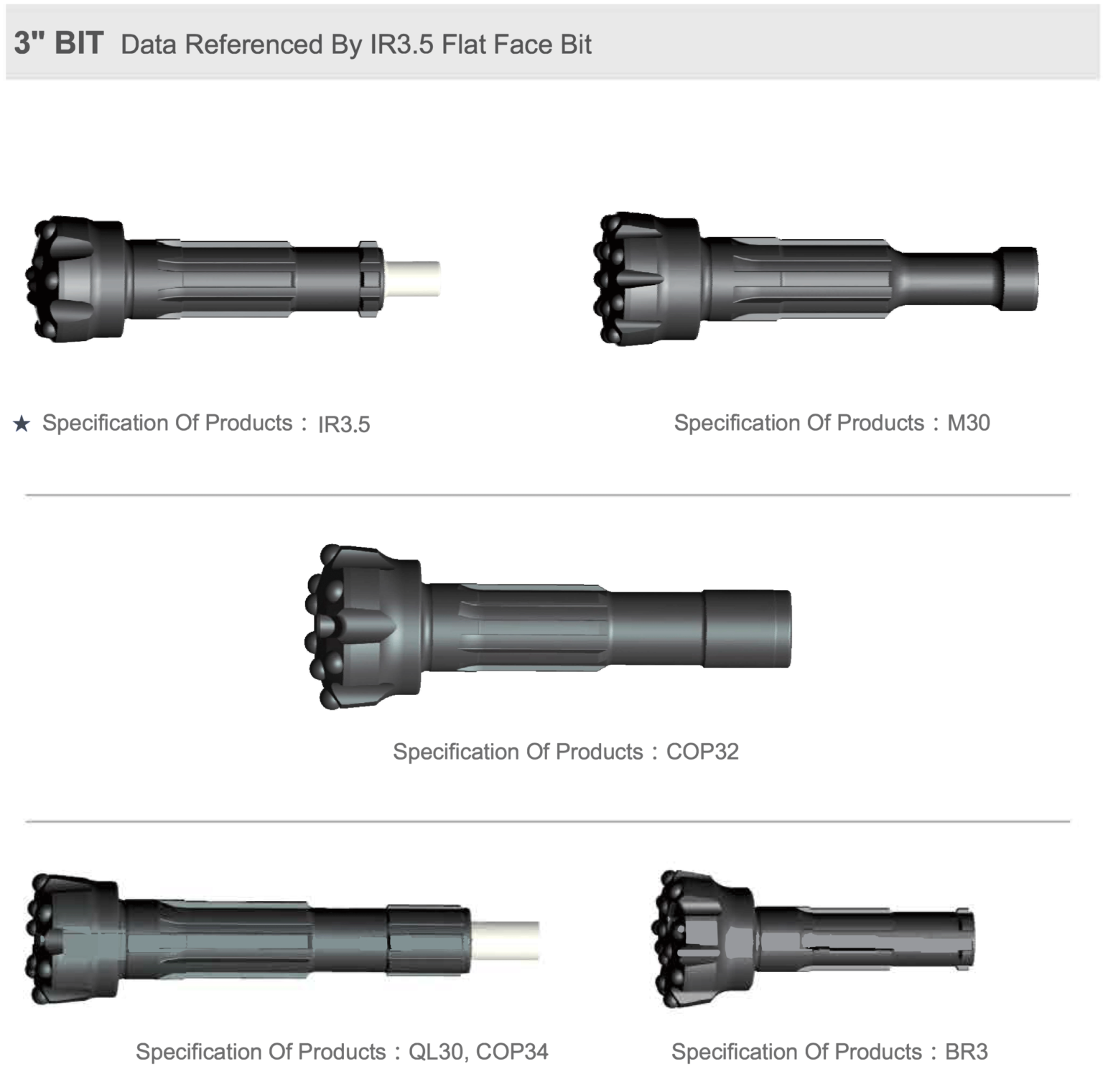

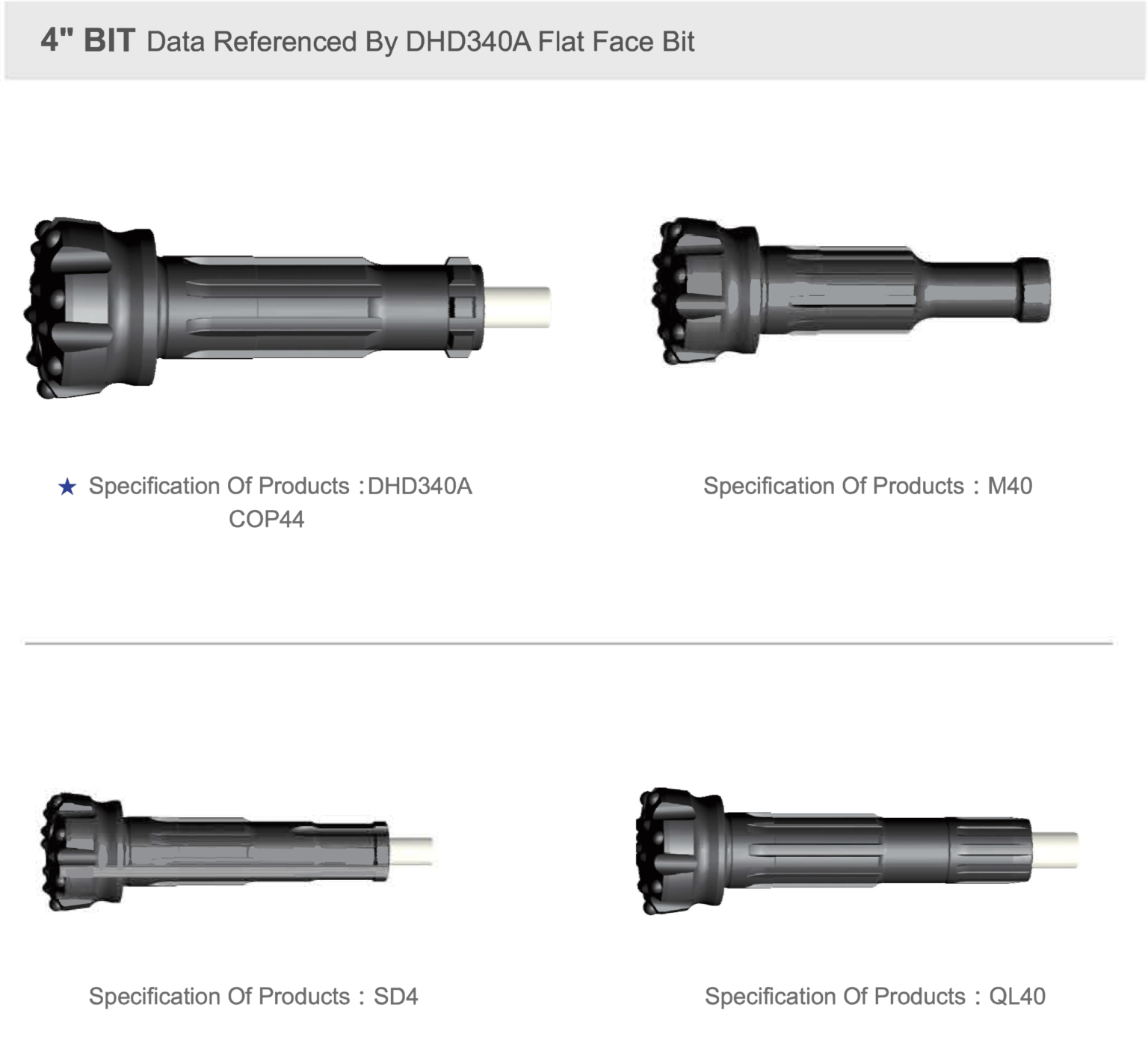

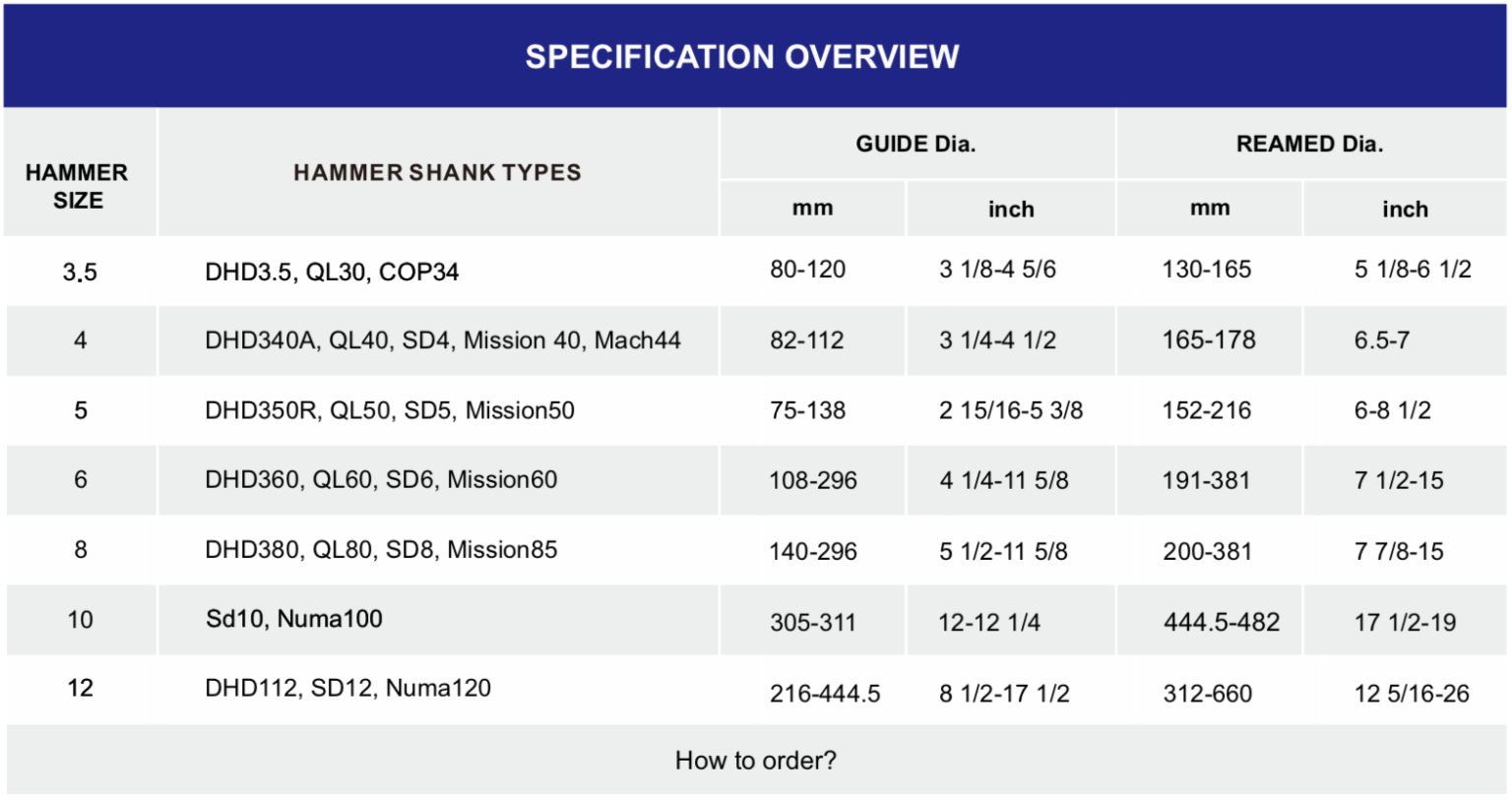

DTH Down the Hole Bit Shanks Selection Chart

DTH Down the Hole Bits Product List

Download PDF

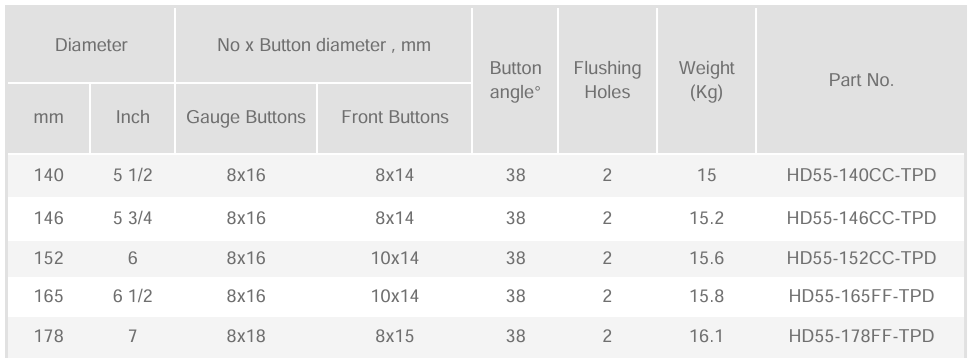

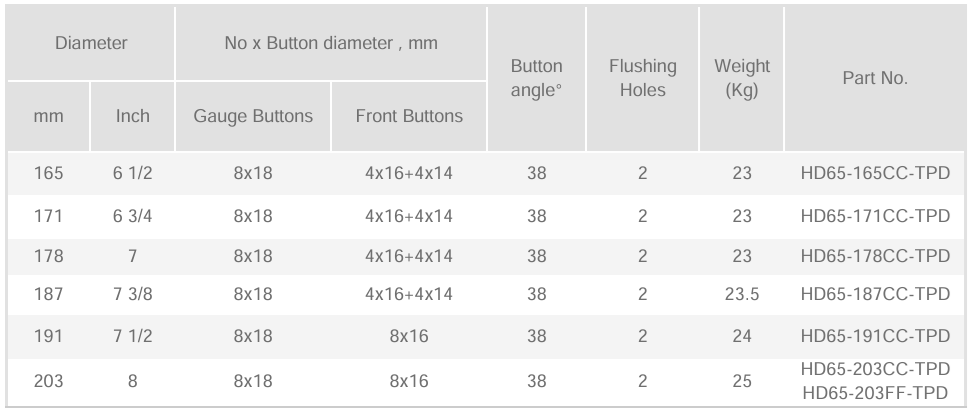

| Diameter | No x Button Diameter, mm | Button Angle° | Flushing Holes | Weight (Kg) | Part No. | ||

| mm | inch | Gauge Buttons | Front Buttons | ||||

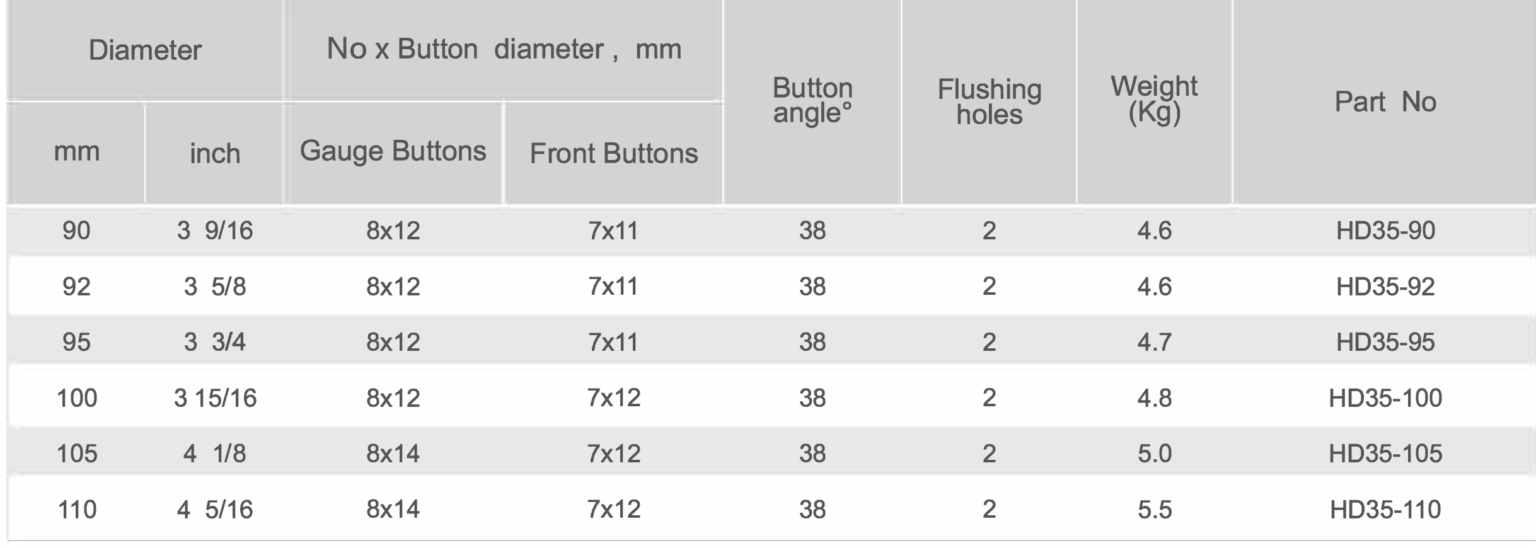

| 90 | 3 9/16 | 8×12 | 7×11 | 38 | 2 | 4.6 | HD35-90 |

| 92 | 3 5/8 | 8×12 | 7×11 | 38 | 2 | 4.6 | HD35-92 |

| 95 | 3 3/4 | 8×12 | 7×11 | 38 | 2 | 4.7 | HD35-95 |

| 100 | 3 15/16 | 8X12 | 7X12 | 38 | 2 | 4.8 | HD35-100 |

| 105 | 4 1/8 | 8×14 | 7×12 | 38 | 2 | 5.0 | HD35-105 |

| 110 | 4 5/16 | 8×14 | 7×12 | 38 | 2 | 5.5 | HD35-110 |

Download PDF

| Diameter | No x Button Diameter, mm | Button Angle° | Flushing Holes | Weight (Kg) | Part No. | ||

| mm | inch | Gauge Buttons | Front Buttons | ||||

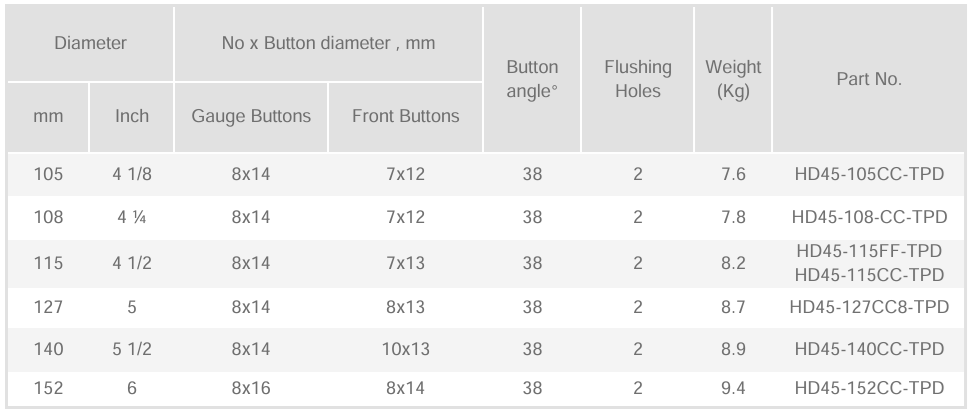

| 105 | 4 1/8 | 8×14 | 7×12 | 38 | 2 | 7.6 | HD45-105CC-TPD |

| 108 | 4 1/4 | 8×14 | 7×12 | 38 | 2 | 7.8 | HD45-108-CC-TPD |

| 115 | 4 1/2 | 8×14 | 7×13 | 38 | 2 | 4.7 | HD45-115FF-TPD HD45-115CC-TPD |

| 127 | 5 | 8×14 | 8×13 | 38 | 2 | 4.8 | HD45-127CC8-TPD |

| 140 | 5 1/2 | 8×14 | 10×13 | 38 | 2 | 5.0 | HD45-140CC-TPD |

| 152 | 6 | 8×16 | 8×14 | 38 | 2 | 5.5 | HD45-152CC-TPD |

DTH Down the Hole - Hole Openers

Download PDF

DTH hole openers are used to enlarge the size of a pilot hole most commonly used in industrial applications. Benefits of drilling a smaller pilot hole are:

- The ability to use less powerful equipment than that required to drill the large diameter hole

- Straighter holes result from the small pilot hole

- Better cleaning of cut material

Black Diamond Drilling Services has a large variety of Hole Openers on the shelf, and if we don’t have what you are looking for we can have one custom-made to your specification.

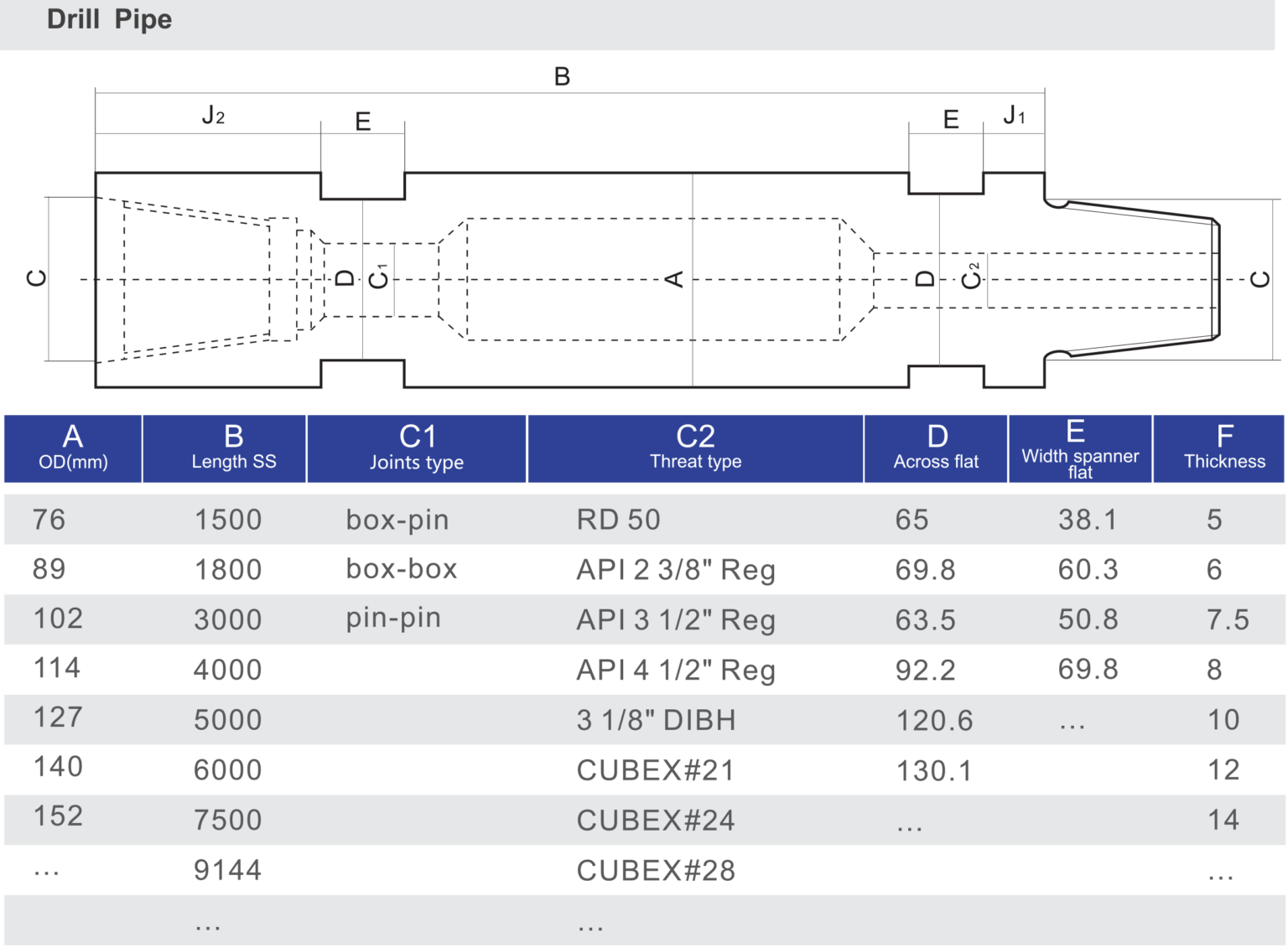

Drill Pipes Specifications and Reference Table

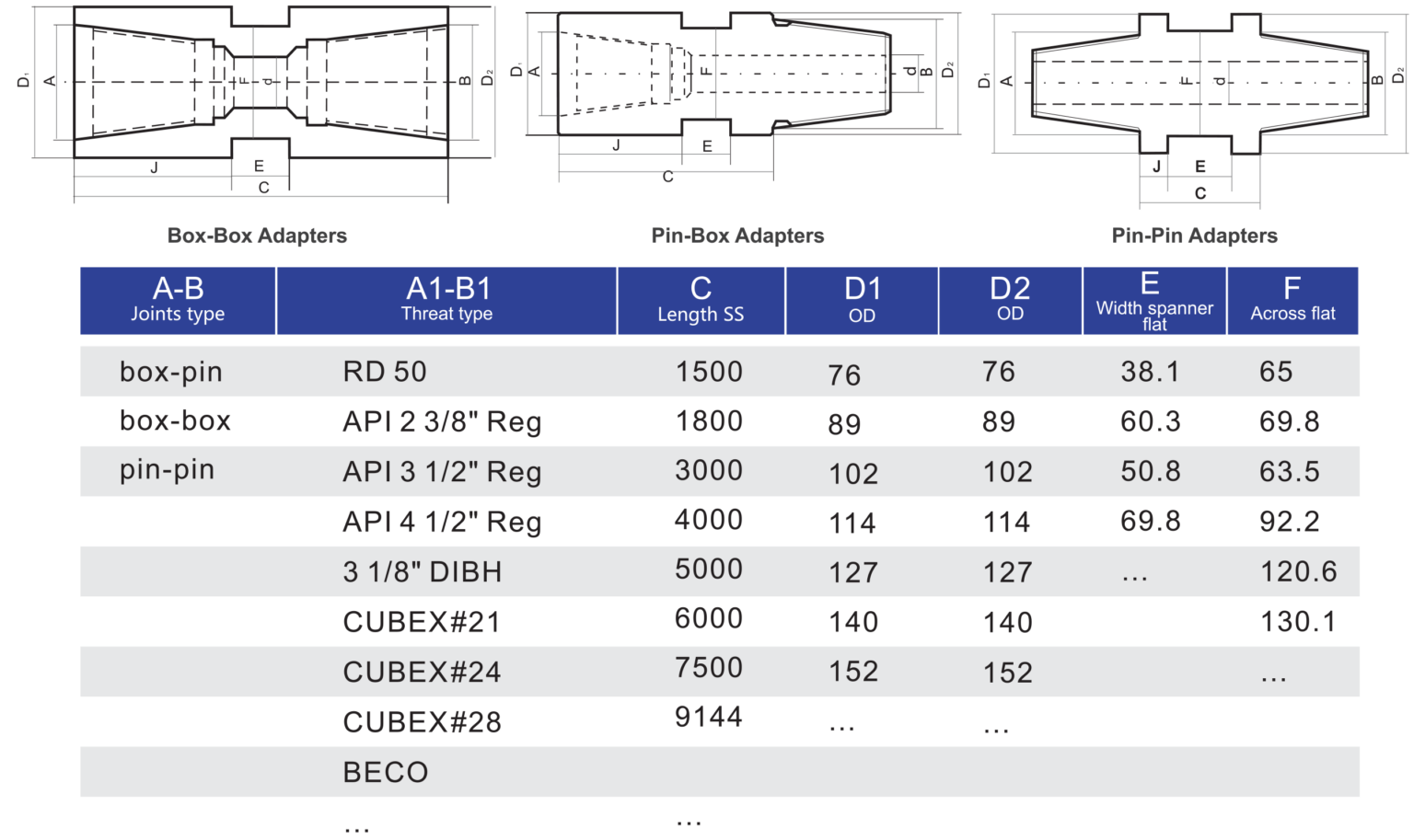

Drill Adapters Specifications and Reference table

Breakout Bench

Download PDF

The threaded connections of the driver chuck and top sub may become very tightly tensioned during drilling. It is convenient to break the hammer threads on the rig, but if the threads cannot be loosened or tend to get stuck, a breakout bench is the solution.

This handy but powerful breakout bench can easily be placed in a workshop or container and it breaks DTH hammers between 3″ and 10″. Select the right breakout bench depending on voltage and power source.