Rotary Drilling Tools

Black Diamond’s Rotary Drilling Tools have been crafted with the highest quality materials. Advanced manufacturing technology and strict quality controls ensure our equipment is durable and reliable. Whether you are exploring potential sites or working an existing mine, BDDRILL bits will guarantee high performance and exceptional reliability.

Rotary Drilling Tools Product Features

Fast Penetration

The cutting structures are designed to perform efficiently and increase the bit life of a variety of insert shapes.

Carbide

Multiple grade selection for different rows of inserts based on function.

Interior Row Inserts

Interior row inserts are critical for high bit life and sustained penetration rates. We select the best inserts for

your application specific products.

Gage Row Inserts

We offer a range of gage row insert shapes suited to all drilling applications. Insert selection is optimised for

all bits in our product range.

Optimized Nozzle Orientation

Nozzle size and orientation are optimised for efficient evacuation of cuttings.

Backflow Valves

Backflow Valves

Backflow valves act as a check valve limiting ingress of water and cuttings to the bit body. This increases the bearing life and reduces the incidence of bearing failure.

By preventing backflow, these valves contribute to maintaining control over the wellbore pressure, reducing the risk of blowouts or uncontrolled releases of formation fluids, which are dangerous and can cause significant damage and downtime.

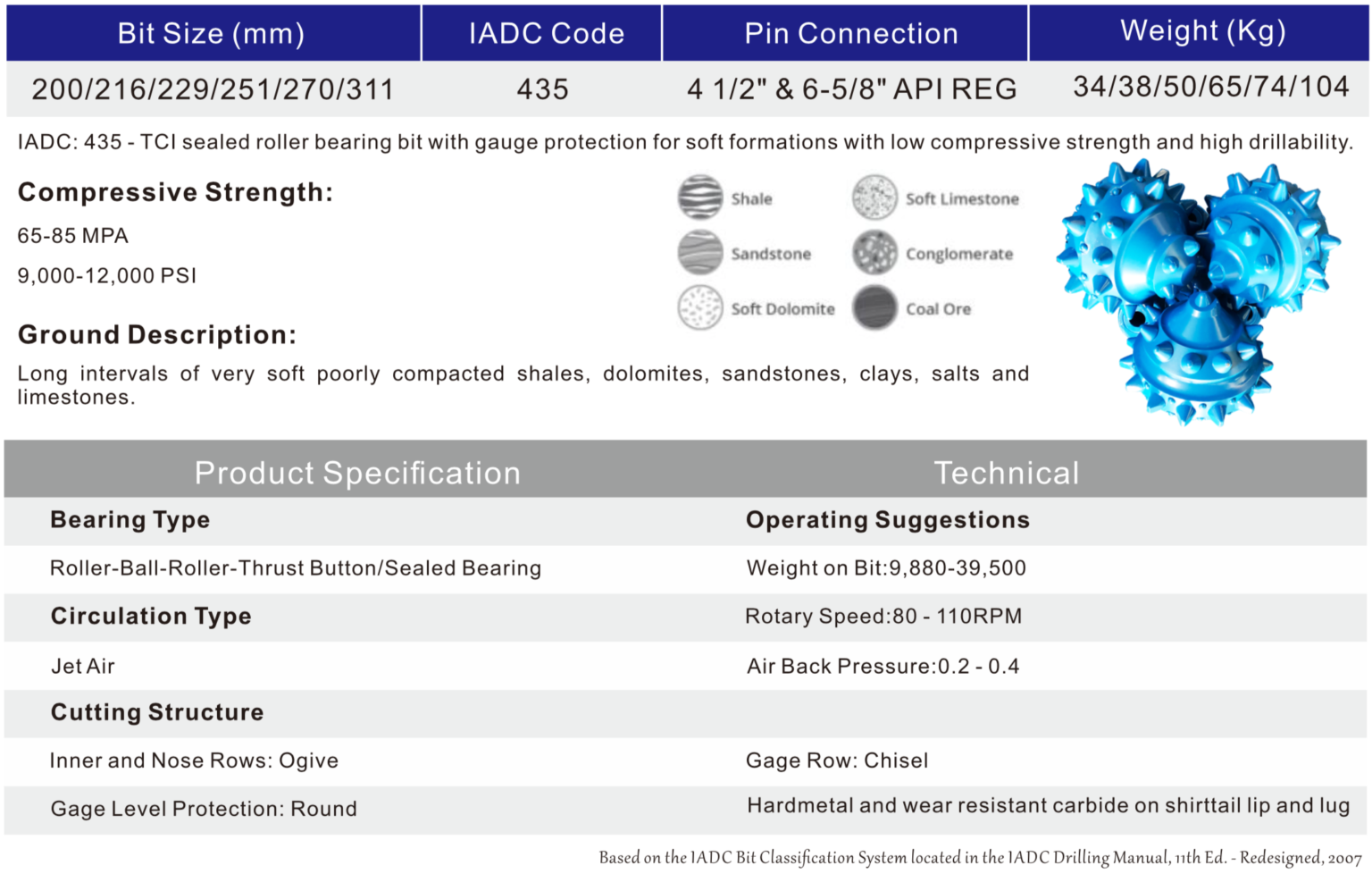

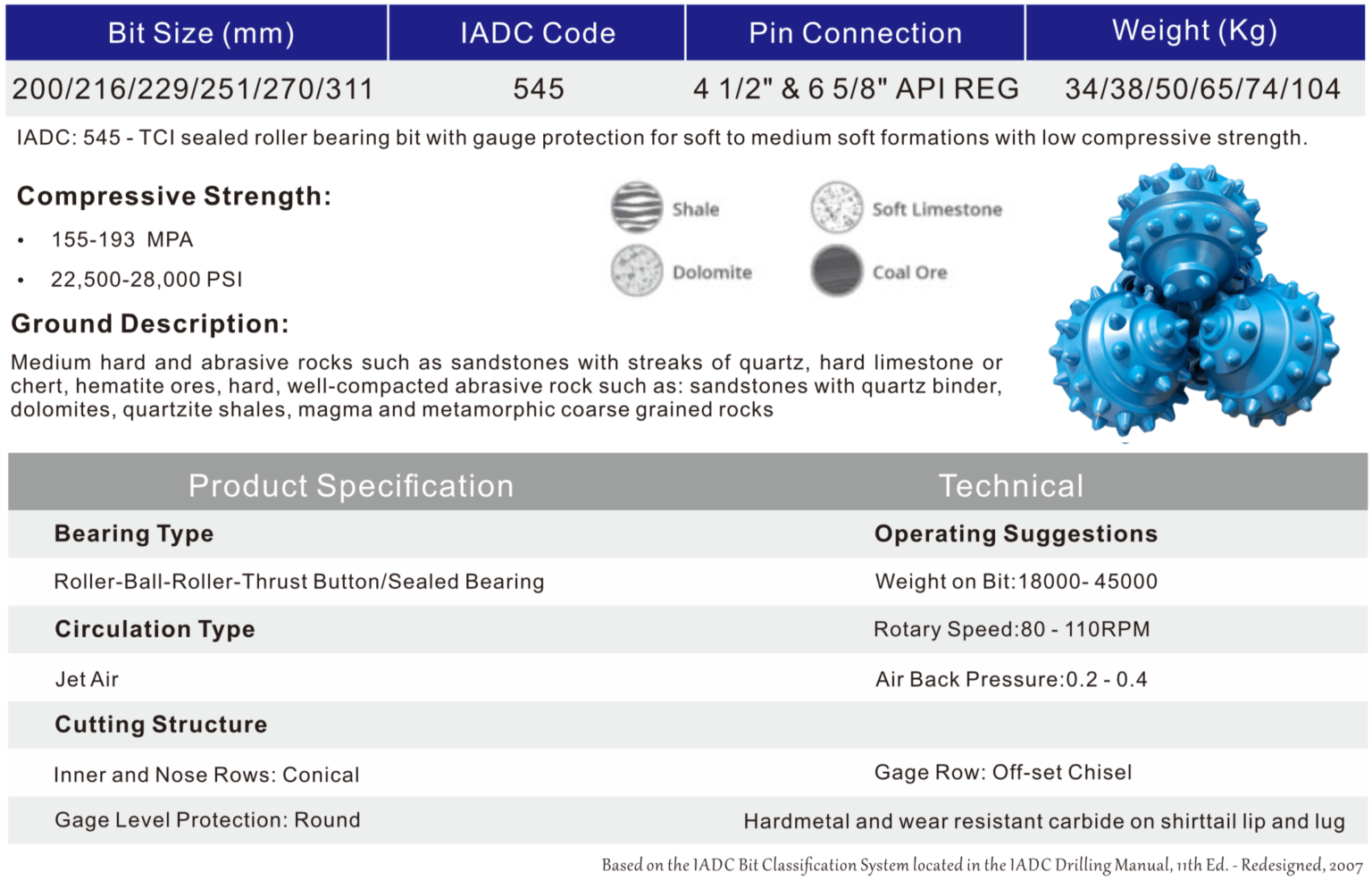

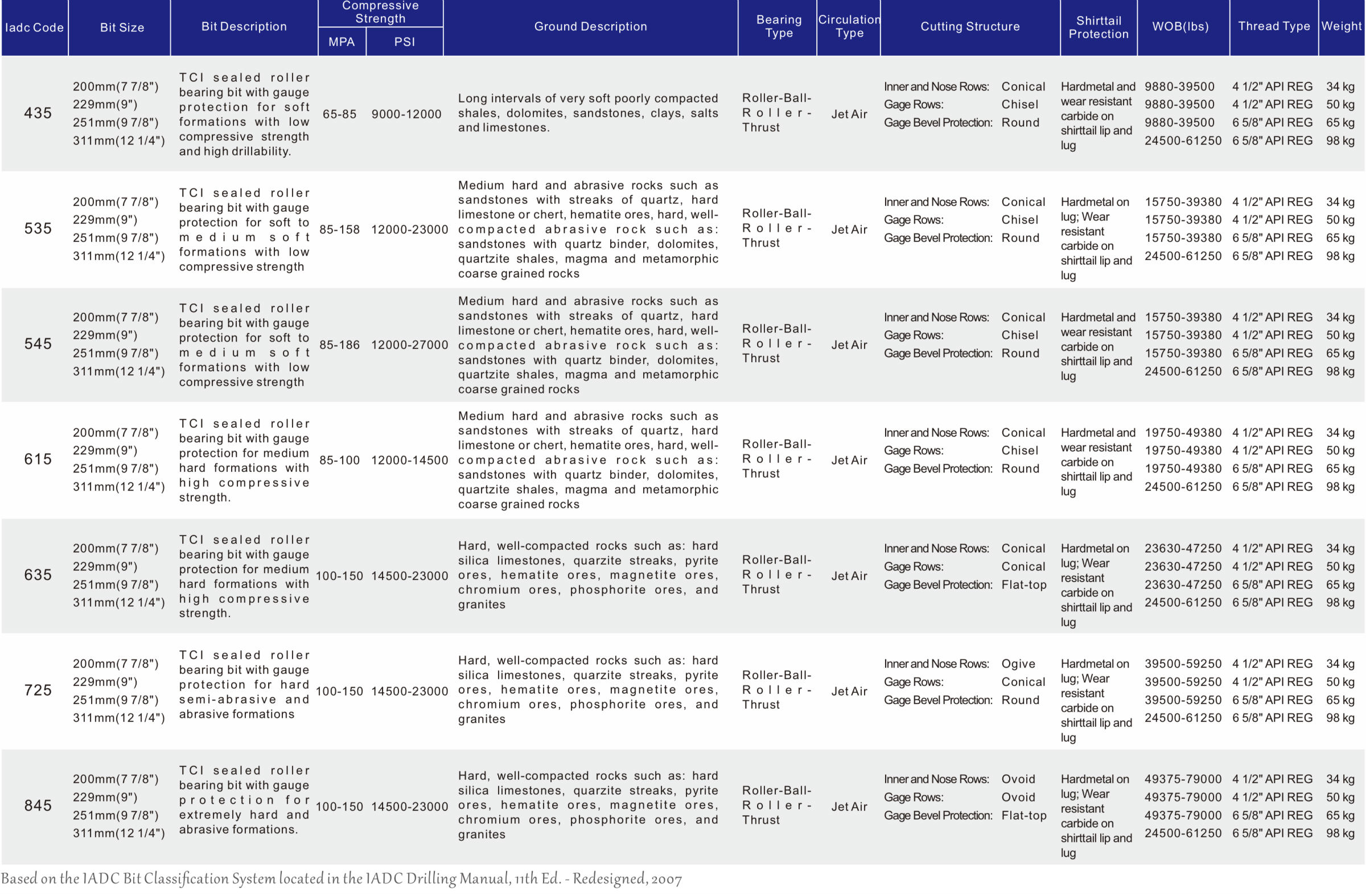

IADC Codes – Rotary Rock Bits

International Association of Drilling Contractors

IADC Codes make it easier for drillers to describe what kind of rock bit they are looking for to the supplier. Black Diamond follows the IADC bit classification system in which the first three digits classify the bit according to the formation is is designed to drill and the bearing/seal design used.

Example 5-4-5-R:

First Digit

a. 1,2 and 3 designate STEEL TOOTH BITS with 1 for soft, 2 for medium and 3 for hard formations

b. 4, 5, 6, 7 and 8 designate TUNGSTEN CARBIDE INSERT BITS for varying formation hardness with 4 being the softest and 8 being the hardest.

Second Digit

1, 2, 3 and 4 are further breakdown of formation with 1 being the softest and 4 the hardest.

Third Digit

This digit will classify the bit according to bearing/seal type (see information on different bearing types) and special gauge wear protection as follows:

1. Standard open bearing roller bit

2. Standard open bearing roller bit, air-cooled

3. Standard open bearing roller bit with gauge protection which is defined as carbide inserts in the heel of the cone

4. Sealed roller bearing bit

5. Sealed roller bearing bit with gauge protection

6. Journal sealed bearing bit

7. Journal sealed bearing bit with gauge protection

Fourth Digit

The following letter codes are used in the fourth digit position to indicate additional features:

A-Air Application / R-Reinforced Welds / C-Center Jet / S-Standard Steel Tooth / D-Deviation Control / X-Chisel insert / E-Extended Jet / Y-Conical Insert / G-Extra Gauge Protection / Z-Other Insert Shape / J-Jet Deflection

Bearing Types

Bearing Types

There are primarily four (4) types of bearing used in tricone drilling bits:

1.) STANDARD OPEN BEARING ROLLER BIT: On these bits the cones will spin freely. This type of bit has a front row of ball bearings \ and a back row of roller bearings.

2.) STANDARD OPEN BEARING ROLLER BIT FOR AIR DRILLING:

Cones are similar to #1, but have air injection directly to the cones to cool the bearings. Air flows into the cone through the passage ways inside the pin. (Not for mud applications)

3.) SEALED BEARING ROLLER BITS: These bits have an O-Ring seal \ with a grease reservoir for bearing cooling. The seal acts as a barrier against mud and cuttings to protect the bearings.

4.) JOURNAL BEARING ROLLER BITS: These bits are strictly oil/grease cooled worth nose bearings, O-Ring seal and a race for maximum performance.

Please check https://www.iadc.org/drillbits/ for more information

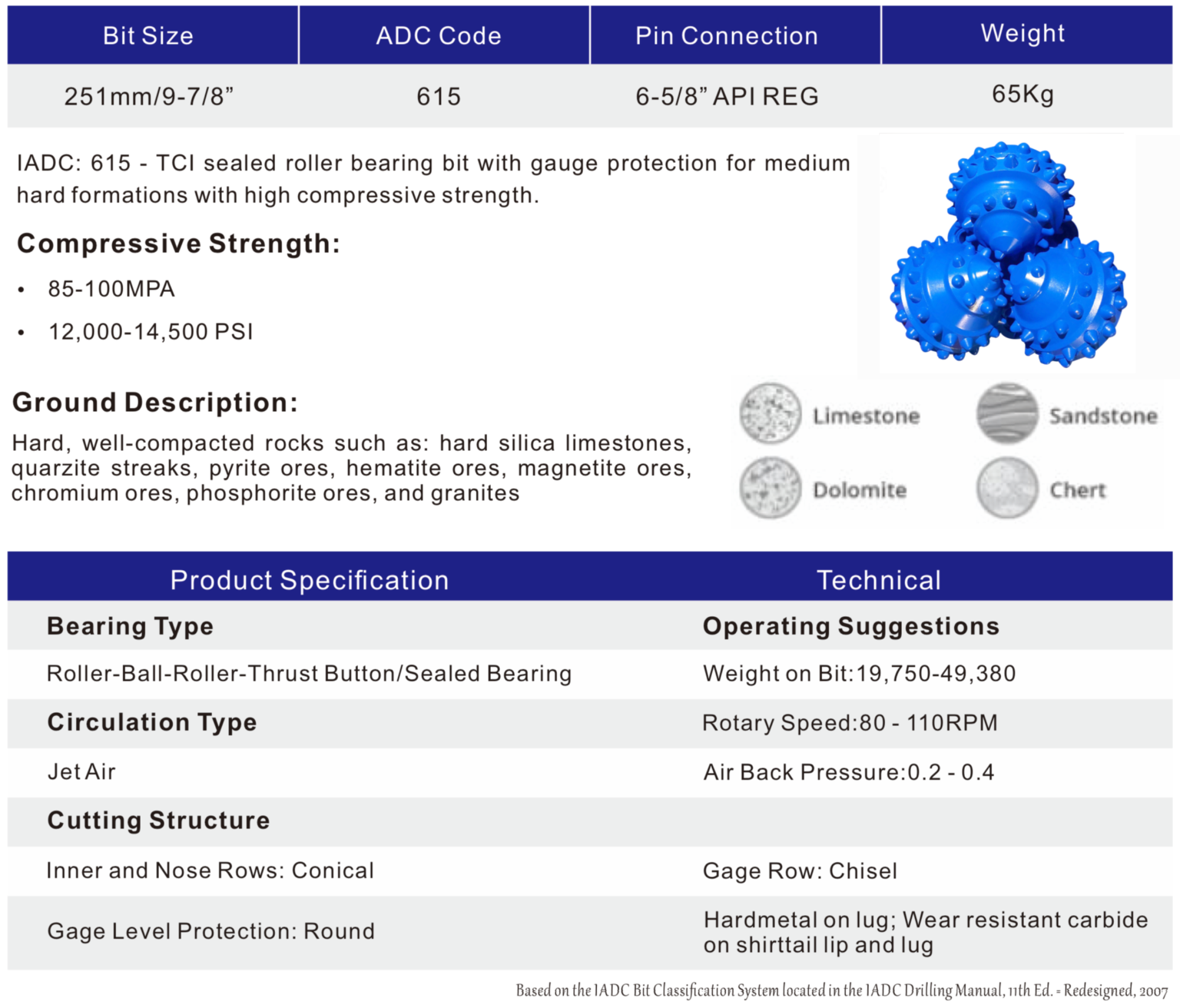

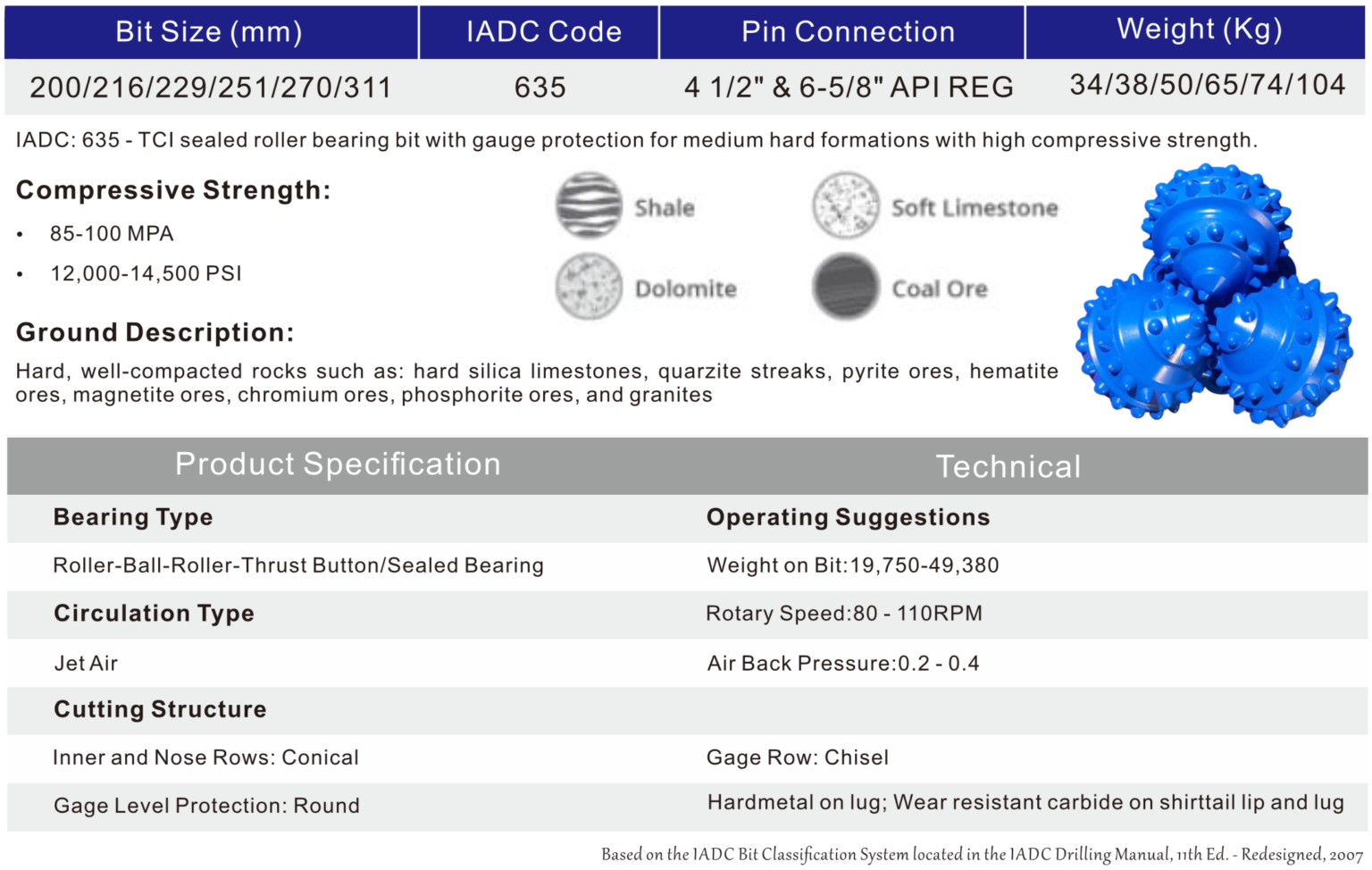

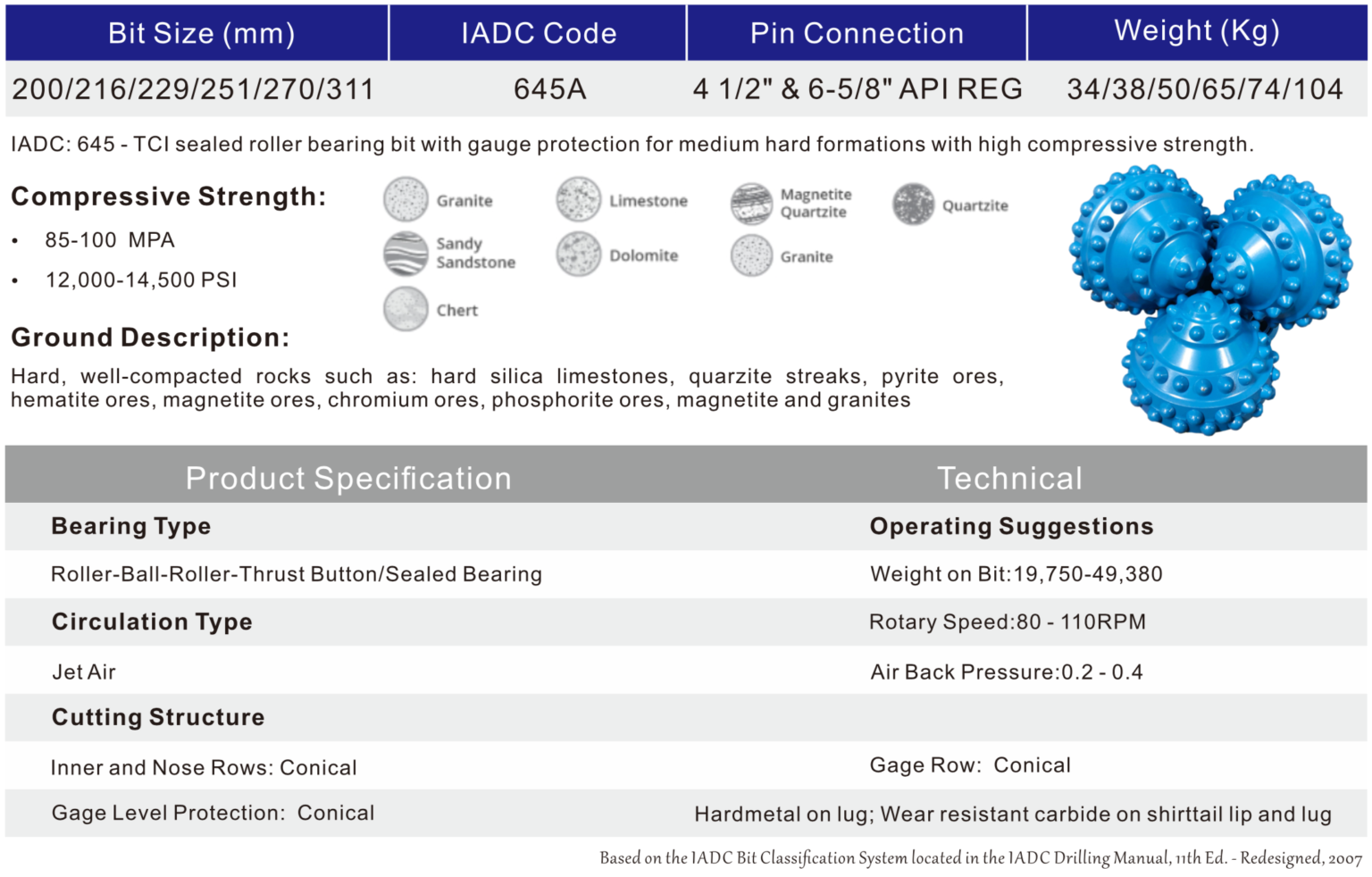

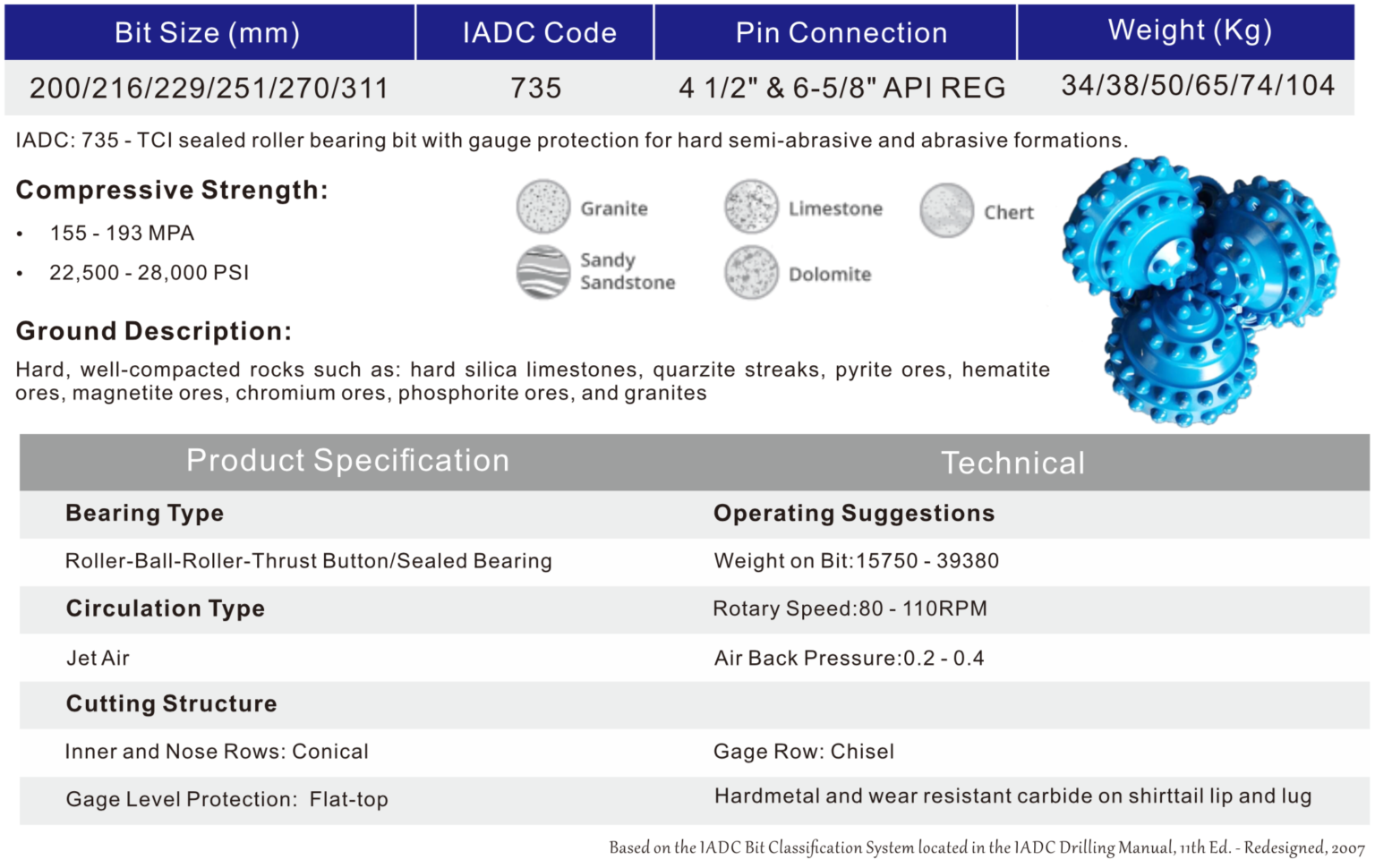

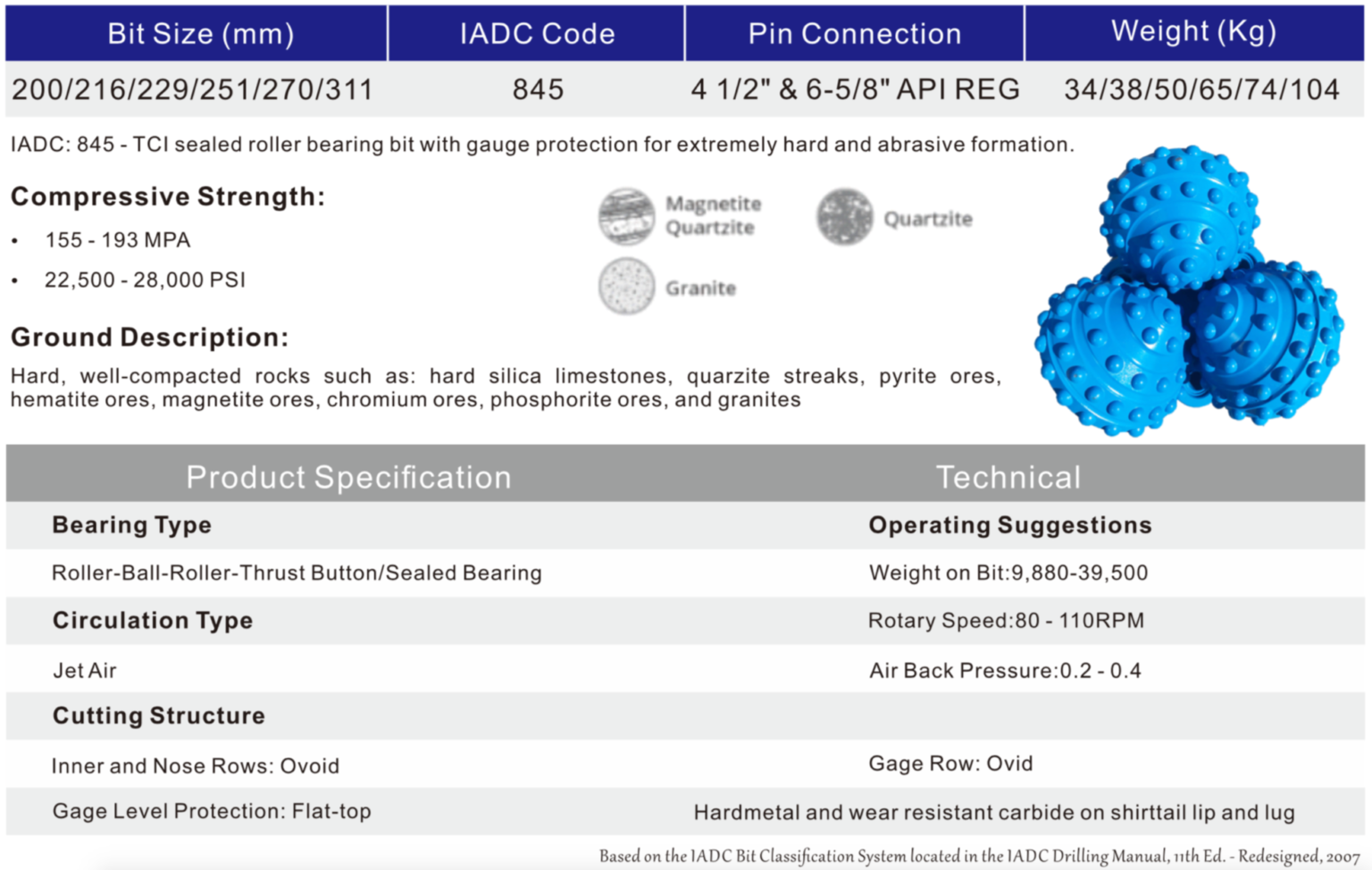

Blast Hole Rotary Bits Specifications

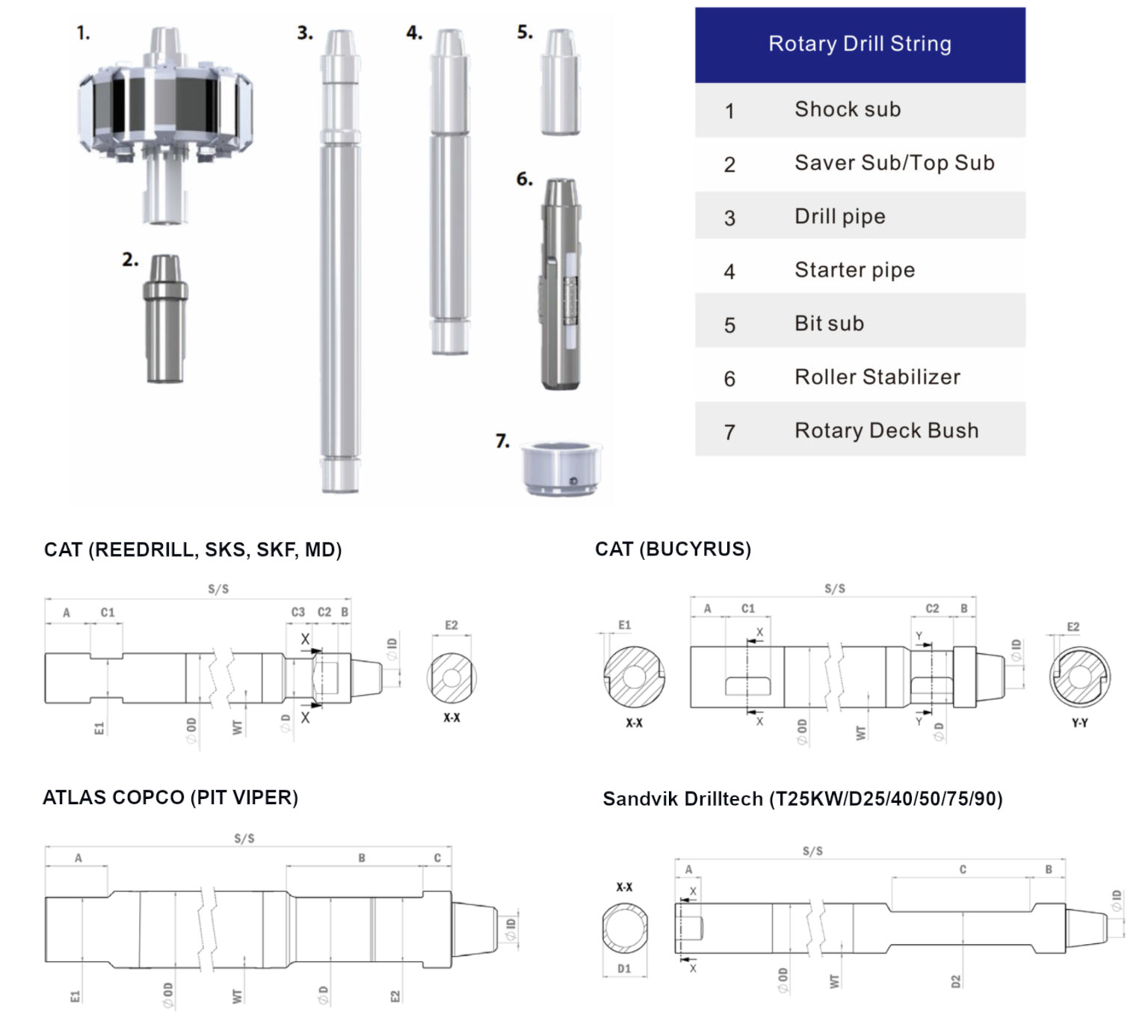

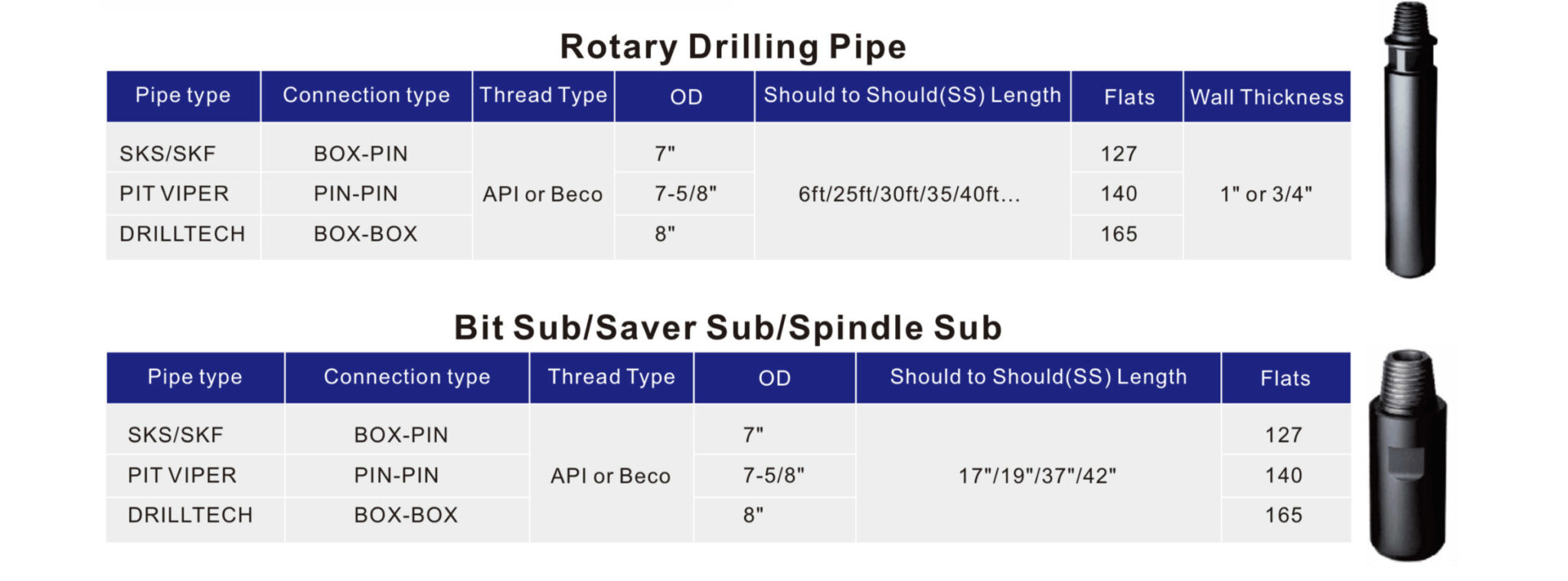

Rotary Drill String Information