Raiseboring tools

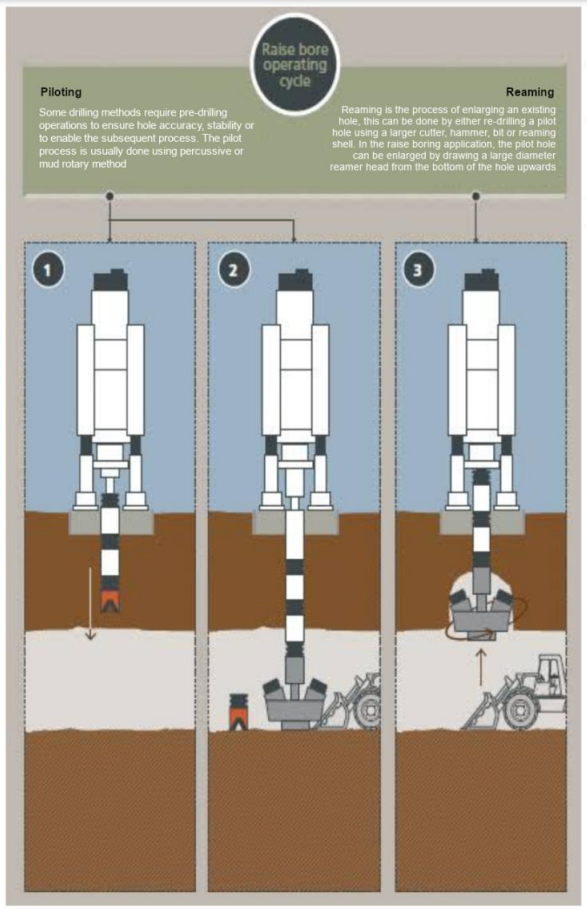

The rotary drilling method of boring large diameter holes for the mining and construction industries has proven to be very cost effective. Raiseboring has gained worldwide acceptance as the preferred method for constructing ventilation and hoisting shafts, ore passes and hydroelectric penstocks.

Tremendous amounts of torque and thrust from drilling machine are transmitted to the cutting head, each individual member of the drill string playing a vital role in the success of the project.

Black Diamond has been involved in the design and development of the threaded connections, material specifications and manufacturing of raise boring tools.

Drill Rods

Both High Strength and Standard Strength drill rods are designed and manufactured with an emphasis on durability, weight reduction, and serviceability. Black Diamond drill rods are designed to be compatible with all of the raise drills operating around the world.

The threaded connections on the rods are cut to exacting standards and verified using precision gauges prior to leaving the factory.

The rods are also designed with features that contribute to long life and serviceability. Each connection is treated in a kemplating process that coats the threads with protection against galling. Anti-galling protection assists in the retention of thread lubricant and the prevention of metal to metal contact. With proper care and maintenance, the threaded connections are designed to provide years of trouble-free service.

Ribbed Stabilizers

Black Diamond six-ribbed stabilizers are designed to stabilize and centralize the drill string. Ribbed stabilizers are critical for the reduction of vibration and to maintain pilot hole accuracy. Joy six-ribbed stabilizers also support and stabilize the cutting head in the reaming cycle. Typically, multiple stabilizers are positioned behind the bit reamer stabilizer during the piloting cycle. When the piloting tools are removed for the reaming cycle, the ribbed stabilizer is connected directly to the reamer.

Ribbed stabilizers are offered with spiral or straight ribs, either tungsten carbide inserts (TCI) or a re-buildable carbide hard-facing. All ribbed stabilizers are finished to exact dimensions across the ribs to suit the pilot hole size for the purpose of achieving optimal stabilization.

Bit Reamer Stabilizers

Black Diamond bit reamer stabilizers are designed to center and stabilize the bit during the pilot hole cycle. They incorporate multiple carbide-tipped rollers that are able to cut and size the hole to finished dimension, effectively compensating for minor pilot bit wear. With a properly-sized pilot hole, normal wear on the ribbed stabilizers can be reduced. Joy bit reamer stabilizers are particularly effective in very hard and abrasive conditions.

The bit reamer stabilizer features carbide inserts pressed into hardened steel rollers that run on hardened steel shafts. All the wear items in the stabilizer, including the rollers, shafts, and retaining blocks, are replaceable. Bit reamer stabilizers are designed to accept standard back flow valves.

Raiseboring Accessories

Thread protectors

Protect your investment from damage due to handling, transportation, moisture and debris. Impact-resistant, high strength Joy thread protectors. Made from non-metallic composite material completely cover the threads and shoulders and resist fading and distortion from heat or cold.

Lifting Bails

Certified lifting bails come complete with shackle and are threaded for connection to your drill rods, stabilizers, or reaming head stems.

Ring Gauges

Use for accurate sizing of all bottom hole components including bits, stabilizers and stems.

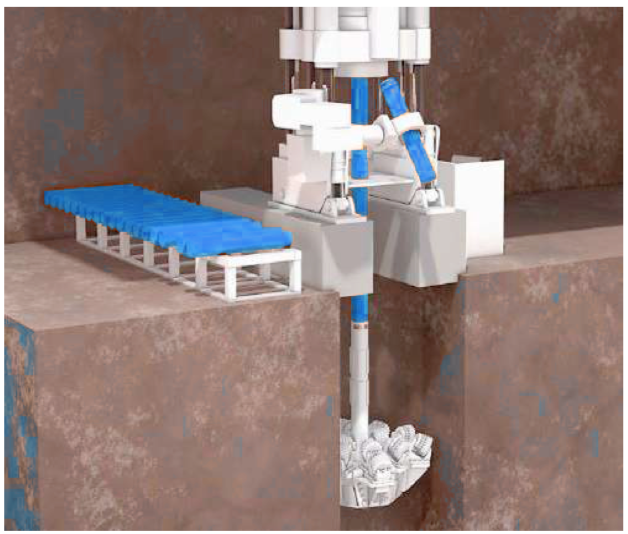

Makeup/Breakout Tools

Manually operated or remote-mounted tools are available to makeup or breakout threaded connections, allowing personnel to work at a safer distance from open hole conditions.

Custom Equipment

In addition to a broad range of standard products, we have extensive experience in engineering and designing customized equipment to suit your specific application.

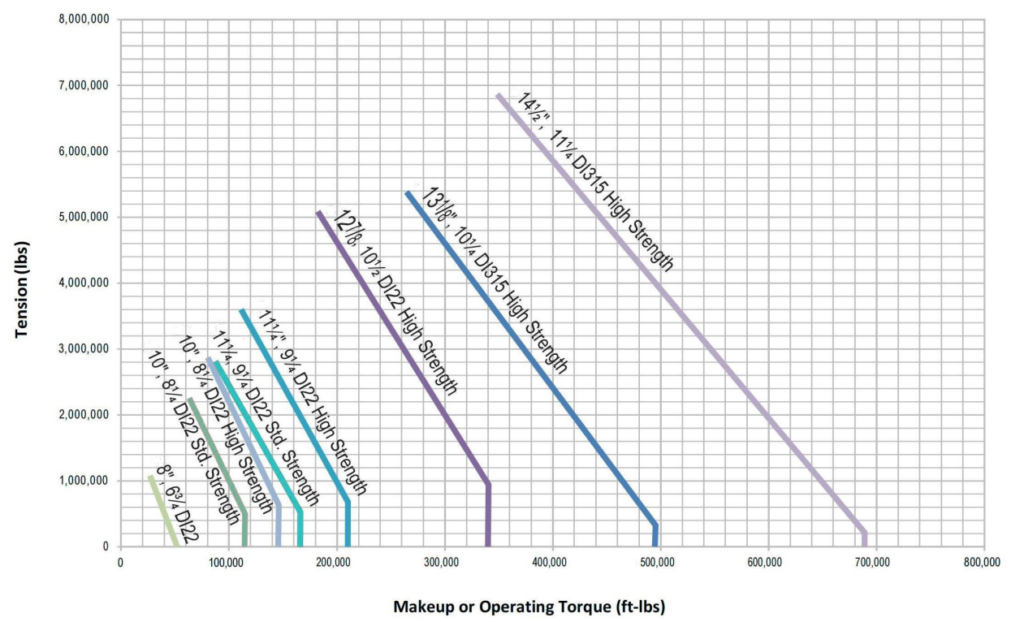

DI connections

The DI22 series of threaded connections was designed and developed specifically for the raiseboring industry. The tapered design of DI22 threaded connections allows for connections to be self centered prior to engagement. Self centering reduces the chance of cross threading or other damage during engagement.. The coarse thread profile is capable of withstanding the extreme torsion and thrust loads that are applied during reaming. Properly lubricated and torqued, the DI22 threaded connections will provide many years of trouble free operation.

In recent years, the DI315 series of threaded connections was developed to meet the needs of the industry as larger, more powerful drills were designed. The unique thread profile and pitch of the DI315 threaded connections were designed to transmit higher levels of torque and thrust than the DI22 series, without the need for a drastic increase in pipe diameter.

To determine the appropriate drill rod and threaded connection to suit your rig’s capabilities for torque and thrust, consult the chart below.