Diamond Drilling Bits

Black Diamond Drilling has a World Class range of Exploration Diamond Drilling Bits including Impregnated Diamond Bits, Surface Set Diamond Bits, CL Diamond Bits, PDC bits, TC bits and Core Lifters.

Bits Classification

Bits can be divided into impregnated bits, surface-set diamond bits, CL diamond bits, PDC bits and TC bits.

Black Diamond’s impregnated diamond drill bits are divided into K series, R series and S series according to the manufacturing process and the matrix heights have C6, C9, C12, C15 and C25.

K series bits are widely used, divided into 6 types of matrix K1, K3, K5, K7, K9 and K11.

R series bits have ultra-wide spectrum, divided into 3 types of matrix R3, R7 and R9.

S series bits can achieve ultra-high matrix, divided into 5 types of matrix S1, S3, S5, S7 and S9.

Surface-set diamond drill bits are brazed with large grain diamonds, which have excellent penetration efficiency. Surface-set diamond bits are widely used in diamond exploration drilling due to their ability to efficiently penetrate hard rock formations and recover core samples for analysis.

| Standard | Number of Waterways | SPC |

|---|---|---|

| NC, HC | 6 | 25/40 |

| NC3, HC3 | 6 | 25/40 |

CL type diamond bits are designed in the structure of gear profile, they are used for drilling in soft formation. It has the characteristics of high efficiency and productivity, superb cooling and powder discharging effect. they have been widely used and achieved great results.

PDC bits are polychrystalline diamond compact bits, they have two kinds of manufacturing process, matrix type and steel type. They are divided into coring type and non-coring type, suitable for soft to medium hard formation. Black Diamond PDC drill bits have various types and are made of high-quality anti-impact oil PDC cutters.

PDC bits are polychrystalline diamond compact bits, they have two kinds of manufacturing process, matrix type and steel type. They are divided into coring type and non-coring type, suitable for soft to medium hard formation. Black Diamond PDC drill bits have various types and are made of high-quality anti-impact oil PDC cutters.

TC drill bits are made of tungsten carbide which is welded onto the drill steel body, they are generally used for drilling soft rock formation namely 1-4 grade sedimentary rocks, quaternary and other strata. Crushed TC drill bits improve drilling efficiency and coring rates in specific environments.

| Item | Type | ||

|---|---|---|---|

| PDC Bit | PDC Coring Bit | PDC Non-Coring Bit | Matrix PDC Bit |

| TC Bit | TC Coring Bit | Non-Coring Bit | Crushed TC Bit |

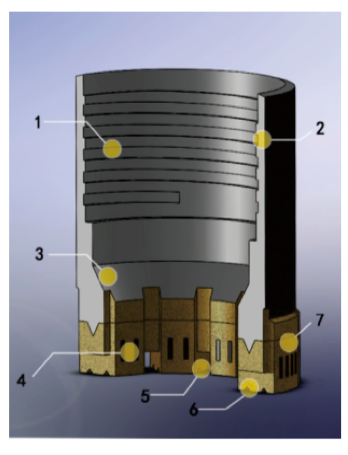

Impregnated Diamond Bits Structure

| Item | Function | |

|---|---|---|

| 1 | Thread | High precision CNC lathe processing, special thread guage inspection |

| 2 | Bit Shank | Made of high quality alloy steel material |

| 3 | Core Lifter Seat Case | Supports core lifter case when breaking core |

| 4 | Tungsten Carbide | High wear ratio polychristalline diameter, increase bit stability |

| 5 | Waterway | Control water flow to cool and remove rock dust |

| 6 | Profile | Ensure the new bit starts working quickly |

| 7 | Crown | Using Pre-alloyed powder, superb impregnate and control diamond, cuts rock |

Impregnated Diamond Bit Matrix

| Classification | Standard Matrix Number | |||

|---|---|---|---|---|

| A, B Size Core Bit | C9-K7 | C9-K9 | ||

| B Size Core Bit | C12-K7 | C12-K9 | ||

| N, H, P Size Core Bit | C9-K3 | C9-K5 | C9-K7 | C9-K9 |

| N, H, P Size Core Bit | C12-K3 | C12-K5 | C12-K7 | C12-K9 |

| S, U Size Core Bit | K7 | |||

| Single & Double Tube Core Bit | C6-K3 | C6-K5 | C6-K7 | C6-K9 |

| Single & Double Tube Bit | C9-K3 | C9-K5 | C9-K7 | C9-K9 |

| Casing Bit, Rod & Casing Shoe | K5 | |||

| Standard Profile | Point profile | |||

| Standard Waterway Numbers | A size 4, B size 6, N size 8, H size 10, P size 12 | |||

| Standard Waterway width | 5.5, 5.5, 7 | |||

| Standard | Standard Matrix Number | ||

|---|---|---|---|

| BC, NC, HC | C12-R3 | C12-R7 | C12-R9 |

| Standard Profile | Point profile | ||

| Standard Waterway Numbers | BD size 6, NC size 8, HC size 10 | ||

| Standard Waterway Width | 5.5mm | ||

| Standard | Standard Matrix Number | ||

|---|---|---|---|

| BC | C15-S9 | ||

| NC, HC | C15-S3 | C15-S7 | C15-S9 |

| NC, HC | C25-S3 | C25-S7 | C25-S9 |

| Standard Profile | Point profile + Turbo waterway | ||

| Standard Waterway Numbers | BC size 6, NC size 8, HC size 10, Fan shaped waterway | ||

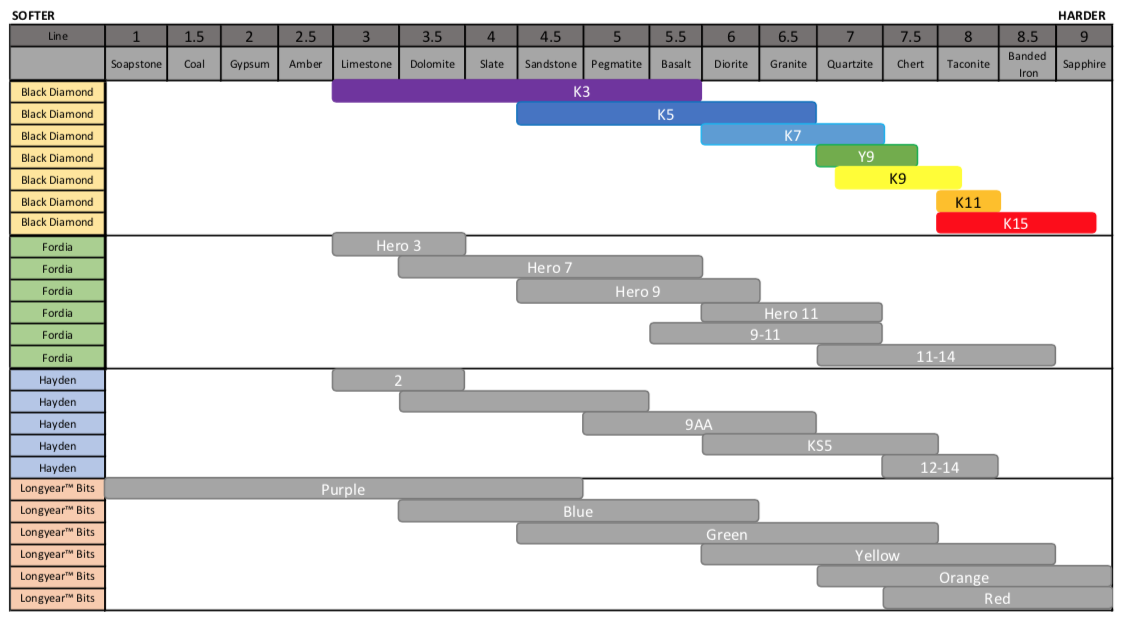

Selection Guideline of Impregnated Diamond Bits Matrix

| Core Bit Configurations | ||||

|---|---|---|---|---|

| Type | Bit Size | Series | Matrix Height | Face Design |

| Diamond | BC | BD3 | 10 | Standard (Pie) |

| Diamond | NC-NC2-NC3 | BD5 | 12 | Turbo |

| Diamond | HC-HC3-HT | BD7 | 14 | Sand Bit (Deep Internal Waterways) |

| Diamond | PC-PC3 | BD8 | 16 | Jet Bit |

| BD9 | 18 | Wedge Waterways | ||

| BD11 | Face Discharge | |||

| BD15 | ||||

| Bit Matrix | K1/S1 | K3/S3 | K5/S5 | K7/S7 | K9/S9 | K11 |

| R3 | R7 | R9 | ||||

| Matrix Hardness | HRC54 | HRC42 | HRC30 | HRC18 | HRC06 | HRC00 |

| Rock Hardness | Select K1 or S1 in case of low working life of K3 or S3 | Select K11 without footage of K9 or S9 |

||||

| Grain Size of the Rock | ||||||

| Breakage of the Rock | ||||||

| Drilling Rig Power | ||||||

| Hardness | Soft Rock | Soft Rock | Soft Rock | Medium Hard Rock | Medium Hard Rock | Medium Hard Rock | Hard Rock | Hard Rock | Extra Hard Rock |

|---|---|---|---|---|---|---|---|---|---|

| Mohs Hardness | 1-2.5 | 3-3.5 | 4 | 4.5 | 5-5.5 | 6-6.5 | 7-7.5 | 8 | 8.5 |

| Boart Longyear ALPHA series | 02 | 02 06ABR 07ABR | 02 06ABR 07ABR | 06ABR 07ABR | 06ABR 07ABR 08ABR 08COM | 08ABR 08COM 09 09COM | 09 09COM 10COM | 09 09COM 10COM |

|

| Boart Longyear UMX series | SSUMX | SSUMX 07UMX | SSUMX 07UMX 09UMX | SSUMX 07UMX 09UMX | SSUMX 07UMX 09UMX | SSUMX 07UMX 09UMX | 07UMX 09UMX 10UMX | 09UMX 10UMX | 09UMX 10UMX |

| ATLAS | 3AC | 7AC | 7AC | 7AC 11AC | 11AC | 11AC 13AC | 13AC | 15AC | |

| FORDIA | HERO3 | HERO7 | HERO7 | 9-11 HERO7 | 9-11 HERO9 | 9-11 HERO11 | 11-14 | 11-14 | |

| BLACK DIAMOND | K1 | K3 | K3/K5 | K3/K5 | K5/K7 | K5/K7/K9 | K7/K9 | K9/K11 | K11 |

| R3 | R7 | R9 | |||||||

| S1 | S3 | S3/S5 | S3/S5 | S5/S7 | S5/S7/S9 | S7/S9 | S9 | K11 | |

| CL Type Bit | |||||||||

| Standard | Water Flow L/min | RPM | Penetration Rate | Weight on Bit | ||||

| in/min | cm/min | lb | kN | |||||

| 200rpi | 250rpi | 80r/cm | 100r/cm | |||||

| T2-46 | 20-30 | 2300 1400 1000 | 11.5 7 5 | 9.2 5.5 4 | 29 18 13 | 23 14 10 | 1,200-2,800 | 9-20 |

| T2-76 | 30-55 | 1350 900 | 6.5 4.5 | 5.2 3.6 | 15 11 | 13 9 | 2,800-5,800 | 14-25 |

| T2-101 | 50-70 | 1000 800 | 5 3.5 | 4 2.8 | 13 9 | 10 7 | 3,800-7,800 | 18-36 |

| AC | 20-40 | 2000 1200 850 | 10 6 4.25 | 8 4.8 3.4 | 25 15 11 | 20 12 9 | 2,000-5,000 | 9-23 |

| BC BC2 | 30-45 | 1700 1000 700 | 8.5 5 3.5 | 6.8 4 2.8 | 22 13 9 | 17 10 7 | 2,000-5,000 | 9-23 |

| NC NC3 | 45-85 | 1350 800 | 6.75 4 | 5.4 3.2 | 17 10 | 14 8 | 3,000-6,000 | 14-27 |

| HC HC3 | 50-100 | 1000 600 | 5 3 | 4 2.4 | 13 8 | 10 6 | 4,000-8,000 | 18-36 |

| PC PC3 | 60-120 | 800 500 | 4 2.5 | 3.2 2 | 10 6 | 8 5 | 5,000-10,000 | 23-45 |

Standard & technical Parameters of Diamond Bits

| Standard | Item | OD*ID(mm) | Matrix Height | Matrix Available | |

|---|---|---|---|---|---|

| 1 | AC | Drill Bit | 47.6*27.0 | C9 | K9 |

| 2 | BC | Drill Bit | 59.5*36.3 | C9, C12 | K7, K9 |

| 3 | BC2 | Drill Bit | 59.5*40.7 | C9, C12 | K7, K9 |

| 4 | NC | Drill Bit | 75.3*47.6 | C9, C12 | K3, K5, K7, K9 |

| 5 | NC2 | Drill Bit | 75.3*50.8 | C9, C12 | K7, K9 |

| 6 | HC | Drill Bit | 95.6*63.5 | C9, C12 | K3, K5, K7, K9 |

| 7 | PC | Drill Bit | 122.0*85.0 | C9, C12 | K3, K5, K7, K9 |

| 8 | SC | Drill Bit | 147.6*102.0 | C12 | K7 |

| Standard | Item | OD*ID(mm) | Matrix Height | Matrix Available | |

|---|---|---|---|---|---|

| 1 | BC3 | Drill Bit | 59.5*33.5 | C12 | K7, K9 |

| 2 | NC3, NCTT | Drill Bit | 75.3*45.0 | C12 | K5, K7, K9 |

| 3 | HC3, HCTT | Drill Bit | 95.6*61.1 | C12 | K5, K7, K9 |

| 4 | PC3, PCTT | Drill Bit | 122.0*83.0 | C12 | K5, K7 |

| Standard | Item | OD*ID(mm) | Matrix Height | Matrix Available | |

|---|---|---|---|---|---|

| 1 | AW | Casing Shoe | 59.5*48.2 | C6 | K5 |

| 2 | BW | Casing Shoe | 75.3*60.2 | C6 | K5 |

| 3 | NW | Casing Shoe | 92.0*76.2 | C6 | K5 |

| 4 | HW | Casing Shoe | 117.6*99.7 | C6 | K5 |

| 5 | HWT | Casing Shoe | 117.6*99.7 | C6 | K5 |

| 6 | PW | Casing Shoe | 143.5*124.5 | C6 | K5 |

| 7 | PWT | Casing Shoe | 143.5*124.5 | C6 | K5 |

| 8 | SW | Casing Shoe | 172.5*146.7 | C6 | K5 |

Bit Range Chart - Black Diamond, Fordia, Hayden, Longyear.

Core Lifters

Standard Core Lifters Features

BD Drill core lifters are made of high-quality alloy steel and are heat treated to increase strength, toughness and wear life.

Diamond-Coated Core Lifters Features

Diamond-coated core lifters add a thin composite diamond-coating (CDC) of a hard metal alloy impregnated with synthetic micro-diamonds. The diamond coating process provides superior wear resistance. Based on field results, the diamond coated core lifter returns approximately 300% longer life as compared to a standard core lifter.

Slotted

- Ideal for use in competent ground conditions

- Increased grip area with the core sample

- Also known as the Brown Style Core lifter

Fluted

- Ideal for broken ground

- Increased flexibility; ideal for use when encountering irregular core

- Also know as Broached Core lifter

Spiral

- Ideal for use in ultra hard ground conditions