Air Requirements

Air Delivery

When rotary blast hole drilling three major factors come into play: Air delivery, Weight on Bit, and RPM. Delivered air needs to provide enough volume, at proper pressure to ensure optimum bearing life when drilling with recommended Pulldown and RPM’s. Sufficient air volume is needed to produce an annular return velocity (Bailing Velocity) of 5,000 feet per minute for normal cuttings. Higher Bailing Velocities are required for wet, heavy cuttings or high penetration rates.

The simple flow equation, Q = vA is used. Since friction losses in the annulus of the relatively shallow holes drilled in blast hole applications are negligible, the flow equation becomes:

Q = V / 183.35 * (D2 – d2)

Q = circulated air volume in cubic feet per minute

V = return velocity in feet per minute

D = hole diameter in inches

d = pipe diameter in inches

Bailing Velocity

Bailing Velocity is the speed of the air that cleans the hole.

The flow equation may also be rewritten to solve for annular velocity V, and for our purpose the bailing velocity BV, when compressor capacity, hole diameter, and pipe diameter are known.

BV = 183.35 * ACFM / (D2 – d2)

ACFM = actual free air volume delivered in cubic feet per minute

BV = bailing velocity in feet per minute

D = hole diameter in inches

d = pipe diameter in inches

Nozzle Selection

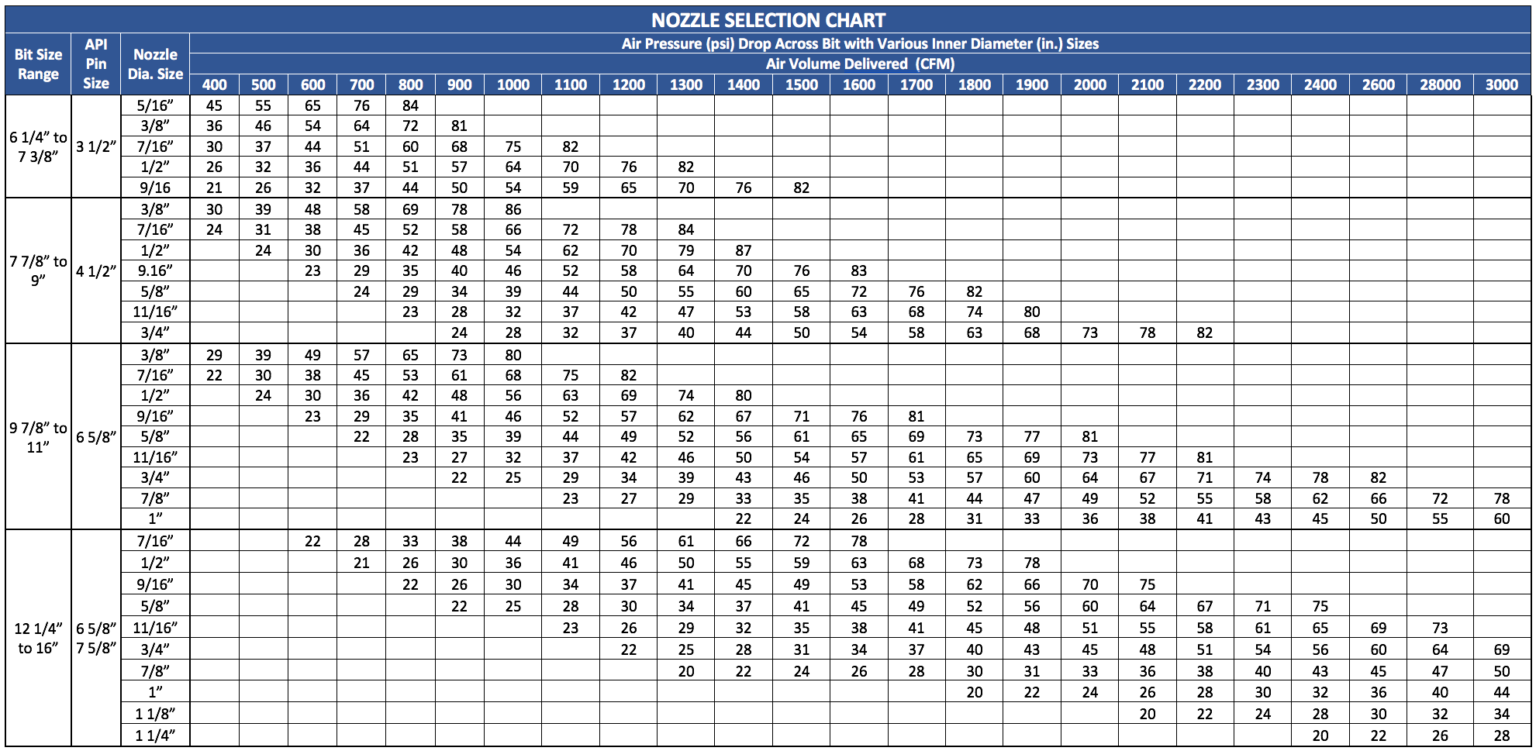

Actual air volume delivered to the bit is a key factor in bearing life and hole cleaning. For optimum bit life and performance, nozzle diameter should be selected to maintain the system pressure close to the maximum allowable limit of the compressor. In addition, to maintain adequate bailing velocities, the pressure drop across the bit must be considered. Other factors include altitude, volumetric efficiency, ambient temperature, and mechanical condition of the compressor.

The chart labeled “Nozzle Selection”, lists the approximate bit operating pressure with reference to air volume delivered and bit diameter, for each selected nozzle size. Actual pressures will depend on bit condition, bearing configuration and drill air piping condition. Pressure drop across bit should always be greater than 40 psi. Remember that there will be 4 – 10 psi in losses in the air system ahead of the bit.